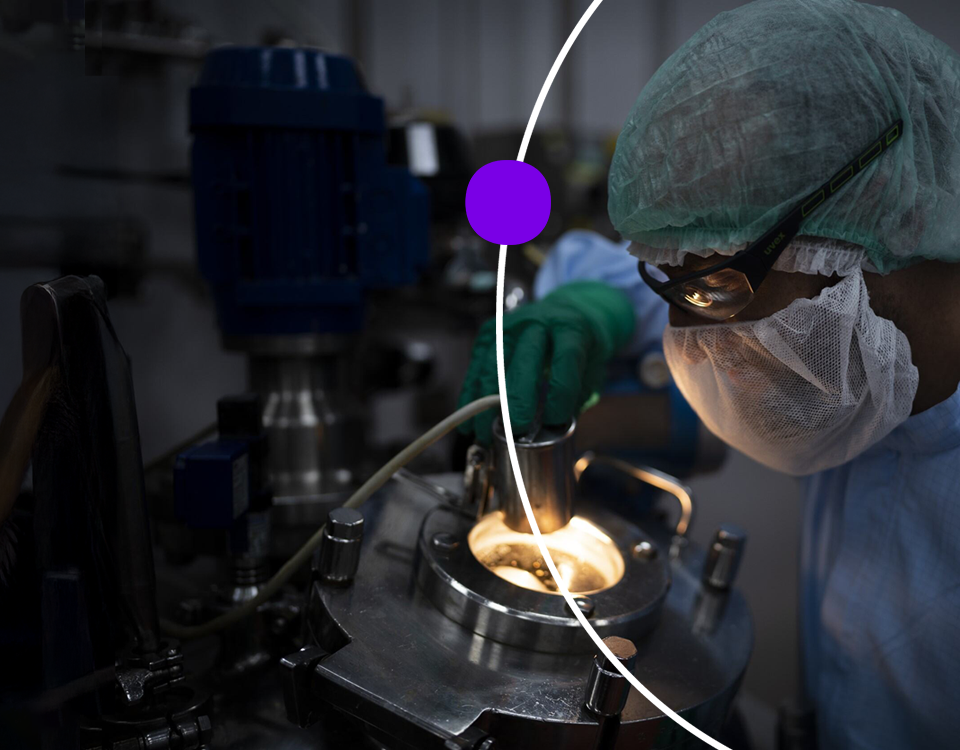

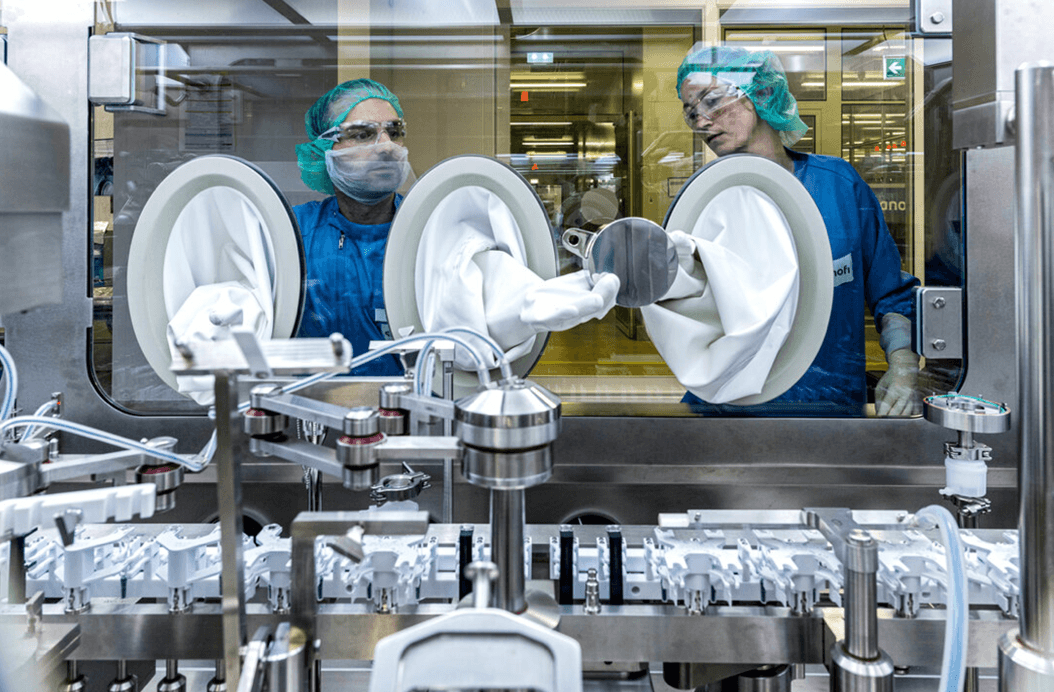

Manufacturing and Supply

Wo Wunder der Wissenschaft

für Patient*innen Realität werden

Quality Associate

Auf einen Blick:

Unsere Teams produzieren und liefern jedes Jahr über 4 Milliarden Einheiten an Medikamenten und Impfstoffen und sorgen dafür, dass jede Innovation die Menschen erreicht, die sie am dringendsten benötigen. Unsere hochmodernen Produktionsstätten, KI-gestützten Smart Factories und wegweisenden Automatisierungstechnologien setzen neue Maßstäbe – damit Behandlungen Patient*innen schneller, sicherer und nachhaltiger als je zuvor erreichen. Hier kannst Du mit Deinen Fähigkeiten, Deinen Ambitionen und Deiner Leidenschaft die Zukunft des Gesundheitswesens mitgestalten.

JOB PURPOSE:

- To manage the overall introduction of new product

- To ensure that affiliate operations are conducted to an adequate level of quality system in conformity with regulatory and internally defined standards

KEY ACCOUNTABILITIES:

1. New product launch readiness

1) Managing the overall introduction of new product by controlling change control

2) Preparing launch by attending regular launch meeting and sharing quality issue

3) Coordinating method transfer

- Cooperate with Sending Unit (SU) and Receiving Unit (RU) to keep the timeline of the technical transfer

- Coordinate import of all the required materials (reference standards, reagents and samples) by preparing the required documents depend on its origin

- Review the protocol and the report for analytical method transfer

- Manage milestone

- If necessary, manage purchasing equipment

4) Setting first QC release test

- Review test method SOPs

- Control stock of all the materials

- Mediate lead time for test

5) Managing pre-approval on-site/virtual GMP inspection by communicating with MFDS and overseas manufacturing site

- Act as a point of contact between MFDS inspectors and the manufacturing iste

- Arrange the schedule and the required logistics (interpreters, accommodation, transportation, etc.)

- Participate on-site/virtual inspection as the affiliate responsible and provide necessary support to both MFDS inspectors and the manufacturing site

- Arrange preparation and submission of CAPA response

2. Quality System

1) Quality Document management (Provide support as back-up)

(1) Procedure management as Local SME

(2) Local QD Management

- Prepare and monitor local quality QD plan and report

(3) Monitoring global QD update and managing QD assessment

- Monitoring global QD creation/revision and assigning the assessment to the relevant Local SME

- Monitoring and managing QD assessment to ensure completion in timely manner

(4) Content Management System (Veeva) management

- Local focal point as a key user

2) GxP document and record management

- Procedure management as Local SME

-Monitoring quality document inventory list and perform periodic review

-Control the access to office archiving room and perform annual access review

-Coordinate transfer/retrieval/destruction of paper document and record to IMK (external document archiving party)

-Handwritten and electronic signature management (including Adobe GxP e-sign system access)

-Quality Monthly Data-day

3) Training

(1) Procedure management as Local SME

(2) Training management (Provide support as back-up)

- Manage and monitor GxP training matrix to be updated in timely manner by each country GxP functions

- Establish quality annual training plan and monitor planned training completion as per the annual plan.

- Coordinate quality individual training plan to be established according to GxP training matrix

- Provide AR support for training completion and KPI monitoring

- Provide necessary support for GxP training management to quality and country GxP functions according to local training management procedure

- Guide to GxP division to maintain up-to-date organizational chart

4) Change Control

(1) Procedure management as Local SME (Provide support as back-up)

(2) Change Control process and system (Veeva) management

- Coordinate change control electronic system deployment and maintenance (Provide support as back-up)

- Manage Change Control records as Change Plan Owner in the system

- Weekly completion monitoring (Provide support as back-up)

- Local focal point as a key user (Provide support as back-up)

5) Deviation & CAPA

(1) Procedure management as Local SME (Provide support as back-up)

(2) Deviation & CAPA process and system (Veeva) management

- Coordinate Deviation & CAPA electronic system deployment and maintenance (Provide support as back-up)

- Review and approve Deviation & CAPA as Quality Approver in the system

- Weekly completion monitoring (Provide support as back-up)

- Local focal point as a key user (Provide support as back-up)

6) HA Inspection & Country GxP Audit

(1) Inspection Readiness Tool (IRT) (Provide support as back-up)

- IRT Process management (Global instruction cascade and training)

- Manage IRT Exercise as IRT coordinator

- Report IRT results and mitigation action Progress at country quality review

(2) Inspection management

- Inspection preparation & coordination with related country functions/owners

- Maintain Inspection readiness Kit and provide necessary training

- Inspection and audit record maintenance as site responsible in the electronic system (Veeva)

(3) Procedure management as Local SME

(4) Annual control self-assessment (CSA)

- Data input, response, follow-up regarding quality system

7) Self-inspection

(1) Procedure management as Local SME

(2) Self-Inspection management (Provide support as back-up)

- Planning and monitoring annual self-inspection

- Monitoring CAPA list

(3) Conduct assigned self-inspection as auditor

8) Managing computerized system

- Procedure management as Local SME

- Evaluation of local GxP computerized system and follow up required local actions according to Global SOPs

- Manage and update local inventory list according to the global procedures (Provide support as back-up)

9) Country Quality Review and KPI management

- Annual quality review data preparation as Quality System SME

- KPI reporting data preparation as Quality System SME

- Other quality performance data preparation as Quality System SME

10) Project management

- Provide support to country quality system manager and global quality for project management related to NPI and Quality system

JOB-HOLDER REQUIREMENTS:

Education

- Bachelor’s degree or above in science

- Pharmacist is preferred.

Experience & knowledge

- at least 5 years experiences in pharmaceutical industries

- Knowledge about pharmaceutical regulation and quality assurance system

Core competencies /skills

- English/Korea proficiency is essential

- Project management skills and cross-functional competence

- Presentation skills and strong communication skills

- Excellence in Word, Excel, PowerPoint

Strebe nach Fortschritt. Entdecke Einzigartiges.

Werde Teil von Sanofi und starte mit uns in eine neue Ära der Wissenschaft – wo dein persönliches Wachstum genauso wegweisend ist wie unsere Arbeit. Wir investieren in dich, damit du weiterkommst, schneller denkst und Dinge möglich machst, die vorher undenkbar waren. Du wirst Grenzen verschieben, Gewohntes hinterfragen und smarte Lösungen entwickeln, die direkt bei den Menschen ankommen, für die wir da sind. Bereit, die Wunder der Wissenschaft zu jagen und Leben zu verbessern? Dann lass uns gemeinsam Großes bewegen – und das Außergewöhnliche entdecken.

Bei Sanofi stehen allen die gleichen Chancen offen – unabhängig von Herkunft, Hautfarbe, Religion, Geschlecht, Nationalität, sexueller Orientierung, Alter, Staatsangehörigkeit, Familienstand, Behinderung, Geschlechtsidentität, Veteranenstatus oder anderen gesetzlich geschützten Merkmalen.

Mehr Informationen über diesen Standort

Warum bei uns arbeiten?

- Wir stellen nicht nur Medikamente her – wir bewirken etwas. Unser globales Netzwerk modernster Produktionsstätten sorgt dafür, dass Patient*innen die Behandlungen erhalten, die sie brauchen – genau zur richtigen Zeit.

- Innovation treibt uns an. Von KI-gestützter Fertigung bis hin zu weltweit führenden Produktionsmethoden setzen wir neue Maßstäbe in Effizienz und Leistung.

- Hier wachsen Karrieren. Ob in der Produktion, Qualitätssicherung, Ingenieurtechnik oder in der Supply Chain– arbeitest Du mit erstklassigen Talenten zusammen, entwickelst Deine Fähigkeiten weiter und gestaltest die Zukunft der Pharmaindustrie mit.

- Wir tun, was richtig ist. Sicherheit, Nachhaltigkeit, Vielfalt, Gleichberechtigung und Inklusion stehen im Mittelpunkt unseres Handelns – für ein Arbeitsumfeld, in dem alle erfolgreich sein können.

All-In für Vielfalt

Bei Sanofi führen unterschiedliche Perspektiven zu den besten Lösungen für Patient*innen. Erfahre von Monique Vessey, unserer Leiterin der Supply Chain -Transformation, wie ihre persönliche Geschichte ihre Arbeit bei der Bereitstellung lebenswichtiger Medikamente prägt.

"Manufacturing & Supply bildet die Brücke zwischen der Wissenschaft in unseren Forschungslaboren und den Menschen und Gemeinschaften, die wir versorgen."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Mehr erfahren

Karriere in Manufacturing and Supply

Entdecke wie Sanofi die pharmazeutische Produktion und Supply Chain mit modernster Technologie, digitaler Innovation und nachhaltigen Prozessen transformiert. Ergreife Deine Chance, lebensverändernde Medikamente effizient und verantwortungsvoll bereitzustellen.

Biopharma-Innovation mit McLaren Racing beschleunigen

Was haben die Formel 1 und die biopharmazeutische Industrie gemeinsam? Geschwindigkeit, Präzision und das Streben nach Exzellenz. Erfahre wie Sanofi gemeinsam mit McLaren Racing die Medikamentenentwicklung mit modernster cutting-edge-Wissenschaft revolutioniert.

Mach mit bei unserer Talent Community

Was können wir gemeinsam erreichen? Unsere Teams arbeiten an Projekten, die Menschenleben nachhaltig verändern. Registriere Dich jetzt und erhalte die neuesten Stellenangebote, sobald diese veröffentlicht werden.