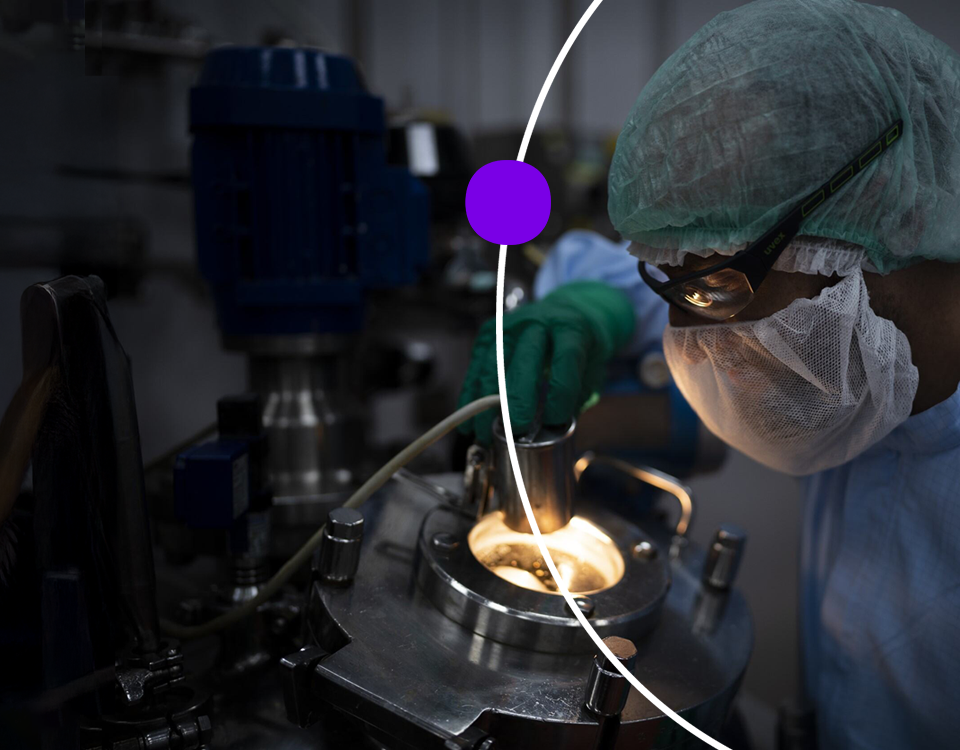

Manufacturing and Supply

Where the

miracles of

science are made

a reality for patients

Quality Associate

At a glance

Our teams produce and deliver over 4 billion units of medicines and vaccines every year, ensuring every breakthrough gets to the people who need it most.

Our state-of-the-art facilities, AI-powered smart factories, and cutting-edge automation are redefining what’s possible: ensuring treatments reach patients faster, safer, and more sustainably than ever before. This is where your skills, ambition, and passion can shape the future of healthcare.

JOB PURPOSE:

- To manage the overall introduction of new product

- To ensure that affiliate operations are conducted to an adequate level of quality system in conformity with regulatory and internally defined standards

KEY ACCOUNTABILITIES:

1. New product launch readiness

1) Managing the overall introduction of new product by controlling change control

2) Preparing launch by attending regular launch meeting and sharing quality issue

3) Coordinating method transfer

- Cooperate with Sending Unit (SU) and Receiving Unit (RU) to keep the timeline of the technical transfer

- Coordinate import of all the required materials (reference standards, reagents and samples) by preparing the required documents depend on its origin

- Review the protocol and the report for analytical method transfer

- Manage milestone

- If necessary, manage purchasing equipment

4) Setting first QC release test

- Review test method SOPs

- Control stock of all the materials

- Mediate lead time for test

5) Managing pre-approval on-site/virtual GMP inspection by communicating with MFDS and overseas manufacturing site

- Act as a point of contact between MFDS inspectors and the manufacturing iste

- Arrange the schedule and the required logistics (interpreters, accommodation, transportation, etc.)

- Participate on-site/virtual inspection as the affiliate responsible and provide necessary support to both MFDS inspectors and the manufacturing site

- Arrange preparation and submission of CAPA response

2. Quality System

1) Quality Document management (Provide support as back-up)

(1) Procedure management as Local SME

(2) Local QD Management

- Prepare and monitor local quality QD plan and report

(3) Monitoring global QD update and managing QD assessment

- Monitoring global QD creation/revision and assigning the assessment to the relevant Local SME

- Monitoring and managing QD assessment to ensure completion in timely manner

(4) Content Management System (Veeva) management

- Local focal point as a key user

2) GxP document and record management

- Procedure management as Local SME

-Monitoring quality document inventory list and perform periodic review

-Control the access to office archiving room and perform annual access review

-Coordinate transfer/retrieval/destruction of paper document and record to IMK (external document archiving party)

-Handwritten and electronic signature management (including Adobe GxP e-sign system access)

-Quality Monthly Data-day

3) Training

(1) Procedure management as Local SME

(2) Training management (Provide support as back-up)

- Manage and monitor GxP training matrix to be updated in timely manner by each country GxP functions

- Establish quality annual training plan and monitor planned training completion as per the annual plan.

- Coordinate quality individual training plan to be established according to GxP training matrix

- Provide AR support for training completion and KPI monitoring

- Provide necessary support for GxP training management to quality and country GxP functions according to local training management procedure

- Guide to GxP division to maintain up-to-date organizational chart

4) Change Control

(1) Procedure management as Local SME (Provide support as back-up)

(2) Change Control process and system (Veeva) management

- Coordinate change control electronic system deployment and maintenance (Provide support as back-up)

- Manage Change Control records as Change Plan Owner in the system

- Weekly completion monitoring (Provide support as back-up)

- Local focal point as a key user (Provide support as back-up)

5) Deviation & CAPA

(1) Procedure management as Local SME (Provide support as back-up)

(2) Deviation & CAPA process and system (Veeva) management

- Coordinate Deviation & CAPA electronic system deployment and maintenance (Provide support as back-up)

- Review and approve Deviation & CAPA as Quality Approver in the system

- Weekly completion monitoring (Provide support as back-up)

- Local focal point as a key user (Provide support as back-up)

6) HA Inspection & Country GxP Audit

(1) Inspection Readiness Tool (IRT) (Provide support as back-up)

- IRT Process management (Global instruction cascade and training)

- Manage IRT Exercise as IRT coordinator

- Report IRT results and mitigation action Progress at country quality review

(2) Inspection management

- Inspection preparation & coordination with related country functions/owners

- Maintain Inspection readiness Kit and provide necessary training

- Inspection and audit record maintenance as site responsible in the electronic system (Veeva)

(3) Procedure management as Local SME

(4) Annual control self-assessment (CSA)

- Data input, response, follow-up regarding quality system

7) Self-inspection

(1) Procedure management as Local SME

(2) Self-Inspection management (Provide support as back-up)

- Planning and monitoring annual self-inspection

- Monitoring CAPA list

(3) Conduct assigned self-inspection as auditor

8) Managing computerized system

- Procedure management as Local SME

- Evaluation of local GxP computerized system and follow up required local actions according to Global SOPs

- Manage and update local inventory list according to the global procedures (Provide support as back-up)

9) Country Quality Review and KPI management

- Annual quality review data preparation as Quality System SME

- KPI reporting data preparation as Quality System SME

- Other quality performance data preparation as Quality System SME

10) Project management

- Provide support to country quality system manager and global quality for project management related to NPI and Quality system

JOB-HOLDER REQUIREMENTS:

Education

- Bachelor’s degree or above in science

- Pharmacist is preferred.

Experience & knowledge

- at least 5 years experiences in pharmaceutical industries

- Knowledge about pharmaceutical regulation and quality assurance system

Core competencies /skills

- English/Korea proficiency is essential

- Project management skills and cross-functional competence

- Presentation skills and strong communication skills

- Excellence in Word, Excel, PowerPoint

Pursue Progress. Discover Extraordinary.

Join Sanofi and step into a new era of science - where your growth can be just as transformative as the work we do. We invest in you to reach further, think faster, and do what’s never-been-done-before. You’ll help push boundaries, challenge convention, and build smarter solutions that reach the communities we serve. Ready to chase the miracles of science and improve people’s lives? Let’s Pursue Progress and Discover Extraordinary – together.

At Sanofi, we provide equal opportunities to all regardless of race, color, ancestry, religion, sex, national origin, sexual orientation, age, citizenship, marital status, disability, gender identity, protected veteran status or other characteristics protected by law.

Watch 'One day at Sanofi' and check out our Diversity Equity and Inclusion initiatives at sanofi.com

Find out more about this location

Why work with us

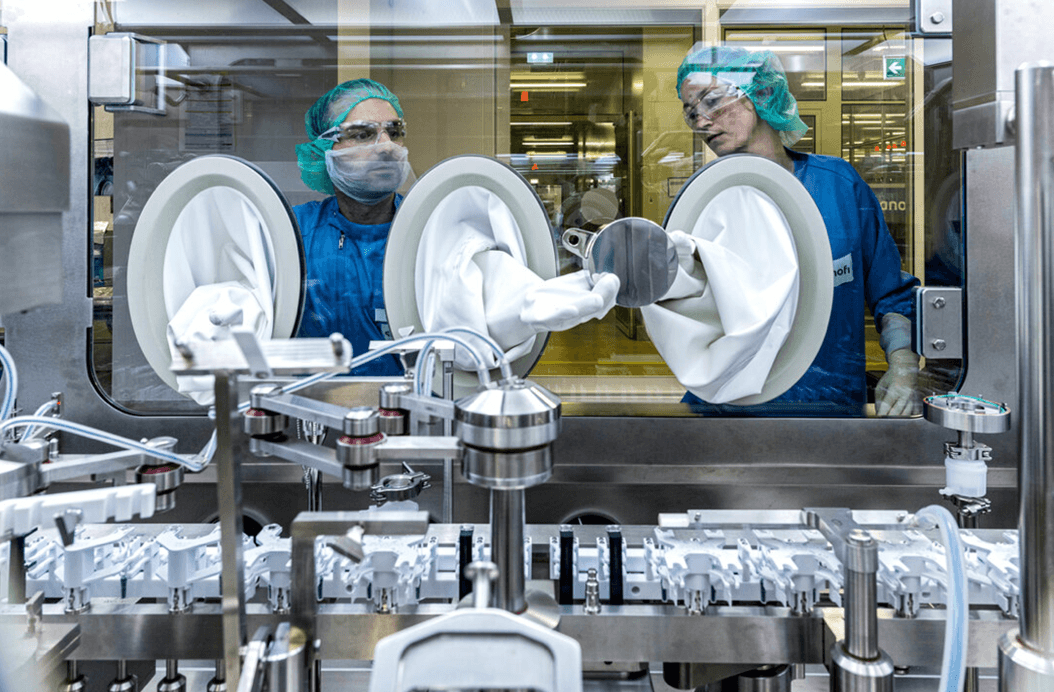

- We’re problem-solvers and pioneers. United by the belief that everyone deserves a healthier future. We create best-in-class vaccines that prevent disease and protect lives.

- Innovation drives us. From AI and mRNA to next-gen science, we push the boundaries to deliver first- and best-in-class vaccines for infectious diseases worldwide.

- Growth happens here. With bold investments in R&D and world-class facilities, Sanofians across the entire vaccine lifecycle are shaping the future of global health.

- We do what’s right. Sustainability and DE&I drive our positive global impact—because the diverse communities Sanofians represent are the patients we serve.

All-in on diversity

At Sanofi, diverse perspectives fuel the best solutions for patients. Hear from Monique Vessey, our Supply Chain Transformation Leader, on how her background shapes her approach to delivering life-changing medicines.

"Manufacturing and Supply is the bridge between the science that happens in research laboratories and the people and communities we serve."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Discover more

Manufacturing & Supply Careers

Explore how Sanofi is transforming pharmaceutical manufacturing and supply chains with cutting-edge technology, digital innovation, and sustainable practices. Discover career opportunities where you can help deliver life-changing medicines efficiently and responsibly.

Accelerating Biopharma Innovation with McLaren Racing

What do Formula 1 and biopharma have in common? Speed, precision, and a drive for excellence. Discover how Sanofi is partnering with McLaren Racing to transform drug development with cutting-edge performance science.

Join our

talent community

What could we achieve together? Every Sanofian works on projects that truly make a difference to people’s lives.

Sign up today and discover our latest opportunities as soon as they’re available.