Manufacturing and Supply

Wo Wunder der Wissenschaft

für Patient*innen Realität werden

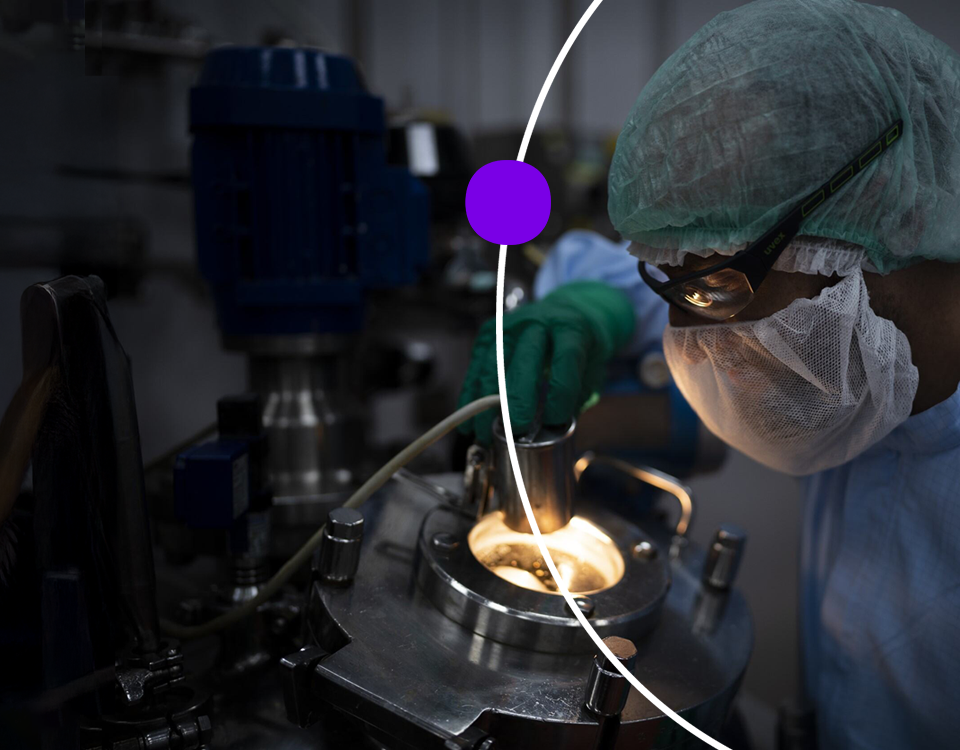

RMF Production Technician

Auf einen Blick:

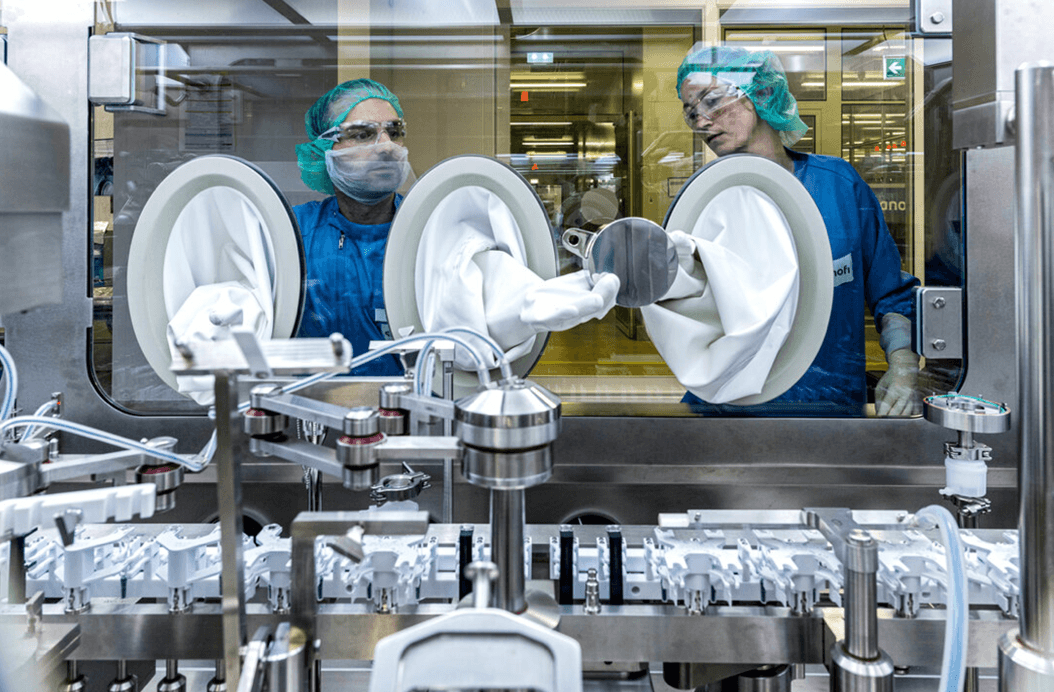

Unsere Teams produzieren und liefern jedes Jahr über 4 Milliarden Einheiten an Medikamenten und Impfstoffen und sorgen dafür, dass jede Innovation die Menschen erreicht, die sie am dringendsten benötigen. Unsere hochmodernen Produktionsstätten, KI-gestützten Smart Factories und wegweisenden Automatisierungstechnologien setzen neue Maßstäbe – damit Behandlungen Patient*innen schneller, sicherer und nachhaltiger als je zuvor erreichen. Hier kannst Du mit Deinen Fähigkeiten, Deinen Ambitionen und Deiner Leidenschaft die Zukunft des Gesundheitswesens mitgestalten.

Job Title: RMF Production Technician

Location: Swiftwater, PA

About the Job

We deliver 4.3 billion healthcare solutions to people every year, thanks to the flawless planning and meticulous eye for detail of our Manufacturing & Supply teams. With your talent and ambition, we can do even more to protect people from infectious diseases and bring hope to patients and their families. Your job, as a Production Technician - Vaccine within our Biologics Team, will have the potential to transform the practice of medicine, turning the impossible into possible for millions of people.

This is a 3rd shift position. Must be able to work weekends and holidays as needed.

This position is to become part of the Production team to support the engineering, construction, qualification, validation, and licensure of the B55 Recombinant Manufacturing Facility. This position contributes as a member of a cross-functional team to support the startup of the cGMP manufacturing facility for Flublok /Panblok drug substance in Swiftwater PA and will later continue to support the cGMP commercial. manufacturing of drug substances requiring a high degree of relationship building, communication, technical knowledge, and leadership.

Sanofi is seeking a motivated professional candidate to operate within Biologics production and perform manufacturing activities. This is an exciting opportunity for a candidate to develop technical skills and learn about the biopharmaceutical industry. The production technician will operate in a cGMP manufacturing area performing equipment set up and operations tasks to meet all standards for safety, quality, and efficiency. The candidate will perform production in accordance with volume fluctuation, business need, and effective procedures.

This position may be required to be moved or temporarily flexed to another department or building within the Biologics operations due to business needs. Additionally, candidates should expect to work in multiple buildings. Some overtime/off shift work hours may be required based on business needs.

The Senior Manufacturing Technician is a technical contributor to Flublok / Panblok manufacturing operations. The role is responsible for supporting the startup of the cGMP manufacturing facility for Flublok / Panblok drug substance in Swiftwater PA and will later continue to support the cGMP commercial manufacturing of drug substances. This role contributes to the overall safety, quality, compliance, productivity, and performance of the Sanofi / Protein Sciences Manufacturing group.

We are an innovative global healthcare company that helps the world stay ahead of infectious diseases by delivering more than 500 million vaccine doses a year. Across different countries, our talented teams are exploring new technologies to protect people and promote healthy communities. We chase the miracles of science every single day, pursuing progress to make a real impact on millions of patients around the world.

Main Responsibilities:

Activities associated with the facility development and project execution will include, but will not be limited to the following:

Support the commissioning, set-up, testing, and qualification of new and existing manufacturing equipment.

Support implementation of Manufacturing Executions System (MES) to optimize control of process management an execution, systems and equipment management, electronic documentation systems, and data historian.

Assist in development of electronic logbooks (eLogbooks) and electronic BRs (eBRs).

Setup, cleaning, and preparation of the manufacturing space to begin the performance of engineering production runs, and lead to process qualification runs and cGMP commercial production.

Participate in execution of Environmental Monitoring Performance Qualification.

Work collaboratively with engineering, validation, quality assurance, quality control, and manufacturing technology groups as well as external stakeholders to accomplish business needs.

Testing of single-use bags and components.

Proactive anticipation and effective communication of successes, constraints, conflicts, solutions, and actions for resolution.

Follows all procedures put into effect to ensure your safety as well as the safety of others. Reports all safety issues, concerns, incidents, and near misses to the team leadership. Provides input for potential safety issues as well as contributing ideas for corrective and preventative actions.

Follows effective procedures to ensure the production of a safe and efficacious product.

Participates or leads in all aspects of production process (SAP, LIMS, ordering, Labwatch, Documentum, Metasys, DeltaV etc.). Understands next steps and works to guide others through the process to complete them.

Understands science behind process steps and technology.

Completes tasks and corresponding documentation as required by cGMP.

Works to become trained in all assigned training modules. Training coordinator / Trainer –Train and guide Personnel in proper work procedures, use of equipment, cGMP’s, safe work techniques and SAP to assure timely signoffs and consistency in training. Maintains qualified trainer status.

This may require input data into SAP, along with entering work orders and reagent orders.

Recommends changes to BRs, SOPS, and SWIs when warranted. Write and edit documents under supervision.

Seeks out cross-training in other areas whenever possible.

Responsible for assisting in writing and assisting incident investigations, CAPA's, change controls, along with assisting the higher-tech levels and Principal Investigators with projects.

Actively communicates improvement ideas, issues, concerns, etc to team members.

Participates in cross-functional teams where necessary to complete projects in an effective and timely manner.

As this project progresses into later phases, the scope of this position will also focus on:

Follow Standard Operating Procedures (SOP) and batch records (BR) to produce commercial drug substance material.

May support updates and changes to SOPs and BRs as required.

Setup, cleaning, sterilization, and use of manufacturing equipment in the cGMP commercial manufacturing of Flublok / Panblok drug substance. May include supporting upstream and/or downstream processes in media or buffer preparation, cell and virus stock production in flasks and bioreactors, centrifugation, chromatography, or filtration; familiarity with this equipment is a plus.

May include support for cleaning, preparation, and sterilization of equipment and parts.

Ensures materials required for production are available as needed.

Works to complete quality documentation (eBR’s, elogbooks, etc) accurately in a timely manner.

Ensures proper process area operation by pre and post-run set up and maintenance of lab and equipment.

Support in housekeeping, facility cleaning, daily manufacturing needs, and the overall compliance within the manufacturing groups. Ensures the manufacturing area is in the inspection-read state.

Provide training, instruction, guidance, and direct support of techniques or operations to operations staff.

Basic understanding of the manufacturing process and the sciences and technology behind process steps.

Supports resolving production issues. Involves appropriate management and team to make decisions for the next steps.

CFR (code of federal regulations) / PAI inspection readiness. FDA audit understanding and awareness.

Supports off-shift work as needed.

All other duties as assigned.

About You

Basic Qualifications:

HS diploma or GED and 2+ years in cGMP or pharmaceutical or warehouse experience, military experience considered

Associates with 1+ years in cGMP or pharmaceutical or warehouse experience, military experience considered

Bachelors with 0+ years in cGMP or pharmaceutical or warehouse experience

Preferred Qualifications:

Prior or related cGMP, Pharmaceutical, or other industrial quality management experience

Proficiency in any of the following areas preferred: Batch record review, environmental monitoring, logbook review, technical writing, SAP, PI historian.

Requires good mechanical skills, computer skills and is detail-oriented. Must have basic mechanical aptitude, good comprehension skills, retention skills, troubleshooting, and manual dexterity.

Special Working Conditions

Ability to lift up to 50 lbs.

Ability to stand on average 8 hours per shift.

Ability to gown and gain entry to manufacturing areas.

Ability to be flexible with work schedule. Potentially modified shifts for training and business needs including holidays and weekend

May require personnel to flex into another platform within MTech and/or another M&S department, as well as the possibility to work weekends, holidays or off shift hours based on business need.

May also include working in an aseptic processing area.

Fit testing requirements of N95 may be required depending on the area you are assigned

Why Choose Us?

Bring the miracles of science to life alongside a supportive, future-focused team.

Discover endless opportunities to grow your talent and drive your career, whether it’s through a promotion or lateral move, at home or internationally.

Enjoy a thoughtful, well-crafted rewards package that recognizes your contribution and amplifies your impact.

Take good care of yourself and your family, with a wide range of health and wellbeing benefits including high-quality healthcare, prevention and wellness programs and at least 14 weeks’ gender-neutral parental leave.

Sanofi Inc. and its U.S. affiliates are Equal Opportunity and Affirmative Action employers committed to a culturally diverse workforce. All qualified applicants will receive consideration for employment without regard to race; color; creed; religion; national origin; age; ancestry; nationality; marital, domestic partnership or civil union status; sex, gender, gender identity or expression; affectional or sexual orientation; disability; veteran or military status or liability for military status; domestic violence victim status; atypical cellular or blood trait; genetic information (including the refusal to submit to genetic testing) or any other characteristic protected by law.

#GD-SP

#LI-SP

#LI-Onsite

#vhd

All compensation will be determined commensurate with demonstrated experience. Employees may be eligible to participate in Company employee benefit programs, and additional benefits information can be found here.

Mehr Informationen über diesen Standort

Warum bei uns arbeiten?

- Wir stellen nicht nur Medikamente her – wir bewirken etwas. Unser globales Netzwerk modernster Produktionsstätten sorgt dafür, dass Patient*innen die Behandlungen erhalten, die sie brauchen – genau zur richtigen Zeit.

- Innovation treibt uns an. Von KI-gestützter Fertigung bis hin zu weltweit führenden Produktionsmethoden setzen wir neue Maßstäbe in Effizienz und Leistung.

- Hier wachsen Karrieren. Ob in der Produktion, Qualitätssicherung, Ingenieurtechnik oder in der Supply Chain– arbeitest Du mit erstklassigen Talenten zusammen, entwickelst Deine Fähigkeiten weiter und gestaltest die Zukunft der Pharmaindustrie mit.

- Wir tun, was richtig ist. Sicherheit, Nachhaltigkeit, Vielfalt, Gleichberechtigung und Inklusion stehen im Mittelpunkt unseres Handelns – für ein Arbeitsumfeld, in dem alle erfolgreich sein können.

All-In für Vielfalt

Bei Sanofi führen unterschiedliche Perspektiven zu den besten Lösungen für Patient*innen. Erfahre von Monique Vessey, unserer Leiterin der Supply Chain -Transformation, wie ihre persönliche Geschichte ihre Arbeit bei der Bereitstellung lebenswichtiger Medikamente prägt.

"Manufacturing & Supply bildet die Brücke zwischen der Wissenschaft in unseren Forschungslaboren und den Menschen und Gemeinschaften, die wir versorgen."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Mehr erfahren

Karriere in Manufacturing and Supply

Entdecke wie Sanofi die pharmazeutische Produktion und Supply Chain mit modernster Technologie, digitaler Innovation und nachhaltigen Prozessen transformiert. Ergreife Deine Chance, lebensverändernde Medikamente effizient und verantwortungsvoll bereitzustellen.

Biopharma-Innovation mit McLaren Racing beschleunigen

Was haben die Formel 1 und die biopharmazeutische Industrie gemeinsam? Geschwindigkeit, Präzision und das Streben nach Exzellenz. Erfahre wie Sanofi gemeinsam mit McLaren Racing die Medikamentenentwicklung mit modernster cutting-edge-Wissenschaft revolutioniert.

Mach mit bei unserer Talent Community

Was können wir gemeinsam erreichen? Unsere Teams arbeiten an Projekten, die Menschenleben nachhaltig verändern. Registriere Dich jetzt und erhalte die neuesten Stellenangebote, sobald diese veröffentlicht werden.