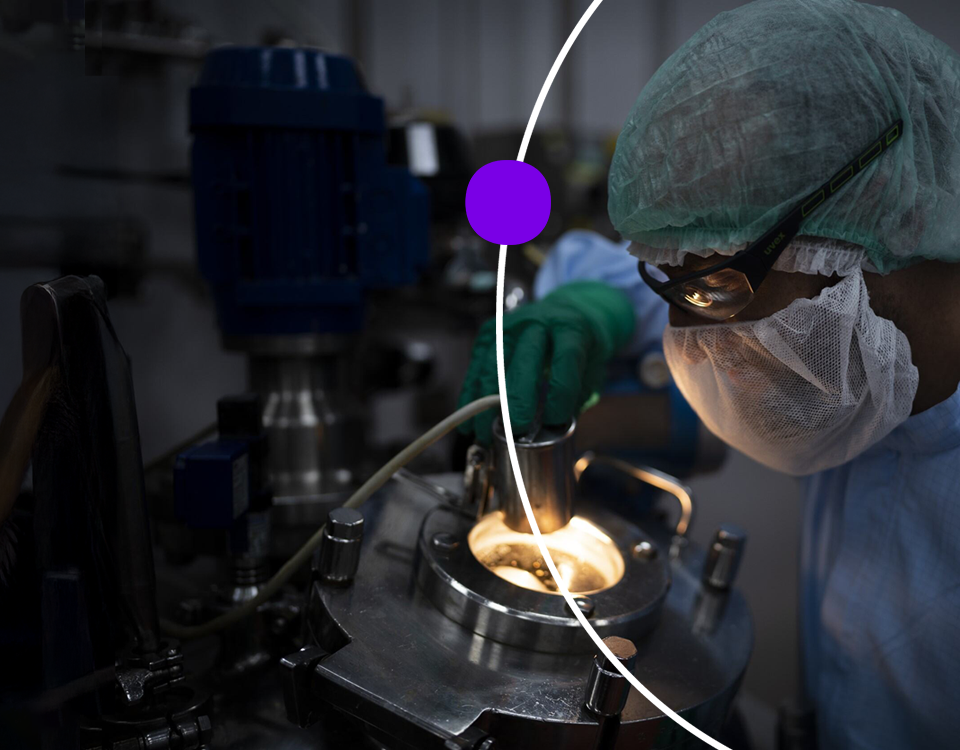

Manufacturing and Supply

Where the

miracles of

science are made

a reality for patients

QA Specialist

At a glance

Our teams produce and deliver over 4 billion units of medicines and vaccines every year, ensuring every breakthrough gets to the people who need it most.

Our state-of-the-art facilities, AI-powered smart factories, and cutting-edge automation are redefining what’s possible: ensuring treatments reach patients faster, safer, and more sustainably than ever before. This is where your skills, ambition, and passion can shape the future of healthcare.

Job title: QA Specialist

Location: Jurong, Singapore

Hiring Manager: Quality Assurance Manager

About the job:

As a Senior Quality Assurance (QA) Operations Specialist, you play a key role in partnering with site GMP operations and validation team in solving complex problems to ensure quality, safety, reliability, efficiencies and manage multiple quality systems including, but not limited to change controls, validation, deviations, laboratory investigations and CAPAs. He/she will assist in the daily operations for Batch Record Review, Batch Disposition/Release, complex deviations and continuous improvement projects. He/she will also ensure the compliance of qualification and validation with applicable regulatory requirements and company quality standards.

Main Accountabilities:

Daily routine GMP documentation review activities (e.g. Batch record review and cleaning records of manufactured batches) of active pharmaceutical ingredients and intermediates in a timely manner by ensuring all the quality aspects of the batches are fulfilled according to GMP requirements.

Daily batch review and release of the manufactured batches i.e., active pharmaceutical ingredients and intermediates to fulfil the cycle time for the key quality indicator.

Participate actively in the GEMBA walk-down during investigation to triage and resolve on-the-floor manufacturing issues. Review and approve investigation by leading complex root cause investigations for manufactured batches that are implicated by Deviation/OOS/OOT/ILI. Highly focus on complex deviation records by ensuring that investigations are deep dive and scientifically justified to withstand scrutiny during the batch review/disposition/release decision.

Monitor the Progress of effective corrective and preventive (CAPA) actions to ensure timely closure of CAPA (key site performance metrics). Collaborate with site operation on problem prevention activities and system improvements.

Support improvement projects by ensuring the validation/qualification are executed with conformance to GMP e.g., review of validation/qualification protocols and reports.

Support in in audits and regulatory inspections (if any). Participating in internal and external audits and inspections, providing necessary documentation and support.

Training: To complete all GMP mandatory and related trainings.

Facilitate daily level 2 quality meeting. Backup as QA Executive for QA team. Support monthly joint GEMBA- backup as QA Specialists for QA team.

Play a pro-active role by complying and adhering to HSE guidelines. Embrace always Zero Incident Mindset and adopt the responsibility of HSE protection policies and Life Saving Rules (LSR).

Other responsibilities that are not included in the above but are related to quality assignments.

Key Involvement in Decision-Making Process

Request corrections when GMP rules are not respected (D)

Request quality improvement initiatives and strategies (D)

Identify discrepancies and corrective/preventive actions that need to be done (D)

Escalate to upper management any failure in GMP execution in shopfloor (I)

Inform relevant stakeholders and team members of quality performance, corrective actions, findings, and preventive measures (I)

Approve a batch record if it is correctly completed and meet the quality requirement for one lot (D)

Check if all practices are done according to quality requirement - if not, assure that a deviation is opened and reported into the batch record (D)

Review documentation for Batches disposition (A)

Proactively implement remediation action from findings from internal and external audits related to quality issues (D)

Advise on quality improvement initiatives and strategies (A)

Escalate the issues when needed (I)

About you

Experience:

You hold a bachelor degree or equivalent from recognised institution with minimum 3-5 years of experience in Quality operation and validation in the pharmaceutical/biotech industry or equivalent holders with a combination of education and relevant work experience.

Quality operational experience is preferred

Meaningful work experience in validation/quality unit in pharmaceutical/biotech industry.

Familiarity with regulatory requirements and local codes & standard e.g., FDA, EMEA and ICHQ7.

Fair knowledge of validation lifecycle approach (URS, FAT/SAT, commissioning, I/O/OQ/PQ protocols etc) and regulatory guidelines in a GMP facility. Familiarity with industry best practices for qualification of SAP system.

Experience with investigations into manufacturing, laboratory deviations and product impact on potential root cause and corrective/preventive actions.

A quick learner with a proactive ‘Can-do’ attitude. Adaptable and flexible in managing rapidly changing priorities, with a commitment supporting site validation activities in alignment with the manufacturing schedule. Discipline and assertiveness in the decision-making and execution of quality related issues.

Exceptional time management skills with strong attention to detail.

Able to work independently and write/review quality validation reports which include equipment /analytical validation and qualification activities. Strong interpersonal relationships in establishing good partnerships with cross functional teams.

Excellent verbal and written communication skills; effective communication and presentation skills across different

Pursue Progress. Discover Extraordinary.

Join Sanofi and step into a new era of science - where your growth can be just as transformative as the work we do. We invest in you to reach further, think faster, and do what’s never-been-done-before. You’ll help push boundaries, challenge convention, and build smarter solutions that reach the communities we serve. Ready to chase the miracles of science and improve people’s lives? Let’s Pursue Progress and Discover Extraordinary – together.

At Sanofi, we provide equal opportunities to all regardless of race, color, ancestry, religion, sex, national origin, sexual orientation, age, citizenship, marital status, disability, gender identity, protected veteran status or other characteristics protected by law.

Watch 'One day at Sanofi' and check out our Diversity Equity and Inclusion initiatives at sanofi.com

Find out more about this location

Why work with us

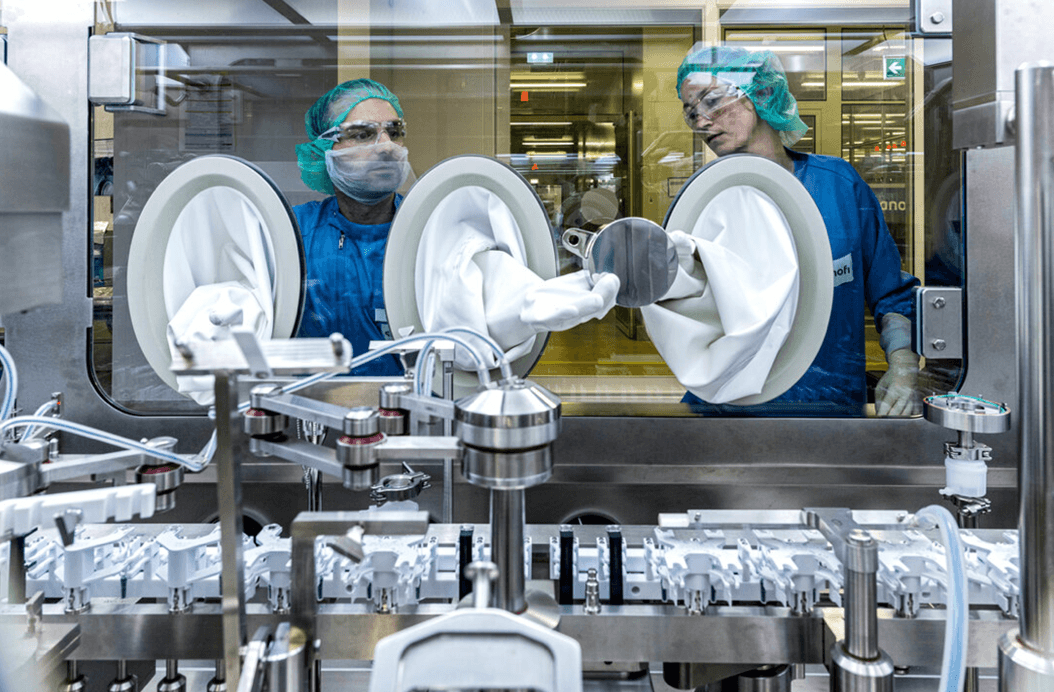

- We’re problem-solvers and pioneers. United by the belief that everyone deserves a healthier future. We create best-in-class vaccines that prevent disease and protect lives.

- Innovation drives us. From AI and mRNA to next-gen science, we push the boundaries to deliver first- and best-in-class vaccines for infectious diseases worldwide.

- Growth happens here. With bold investments in R&D and world-class facilities, Sanofians across the entire vaccine lifecycle are shaping the future of global health.

- We do what’s right. Sustainability and DE&I drive our positive global impact—because the diverse communities Sanofians represent are the patients we serve.

All-in on diversity

At Sanofi, diverse perspectives fuel the best solutions for patients. Hear from Monique Vessey, our Supply Chain Transformation Leader, on how her background shapes her approach to delivering life-changing medicines.

"Manufacturing and Supply is the bridge between the science that happens in research laboratories and the people and communities we serve."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Discover more

Manufacturing & Supply Careers

Explore how Sanofi is transforming pharmaceutical manufacturing and supply chains with cutting-edge technology, digital innovation, and sustainable practices. Discover career opportunities where you can help deliver life-changing medicines efficiently and responsibly.

Accelerating Biopharma Innovation with McLaren Racing

What do Formula 1 and biopharma have in common? Speed, precision, and a drive for excellence. Discover how Sanofi is partnering with McLaren Racing to transform drug development with cutting-edge performance science.

Join our

talent community

What could we achieve together? Every Sanofian works on projects that truly make a difference to people’s lives.

Sign up today and discover our latest opportunities as soon as they’re available.