Manufacturing and Supply

Where the

miracles of

science are made

a reality for patients

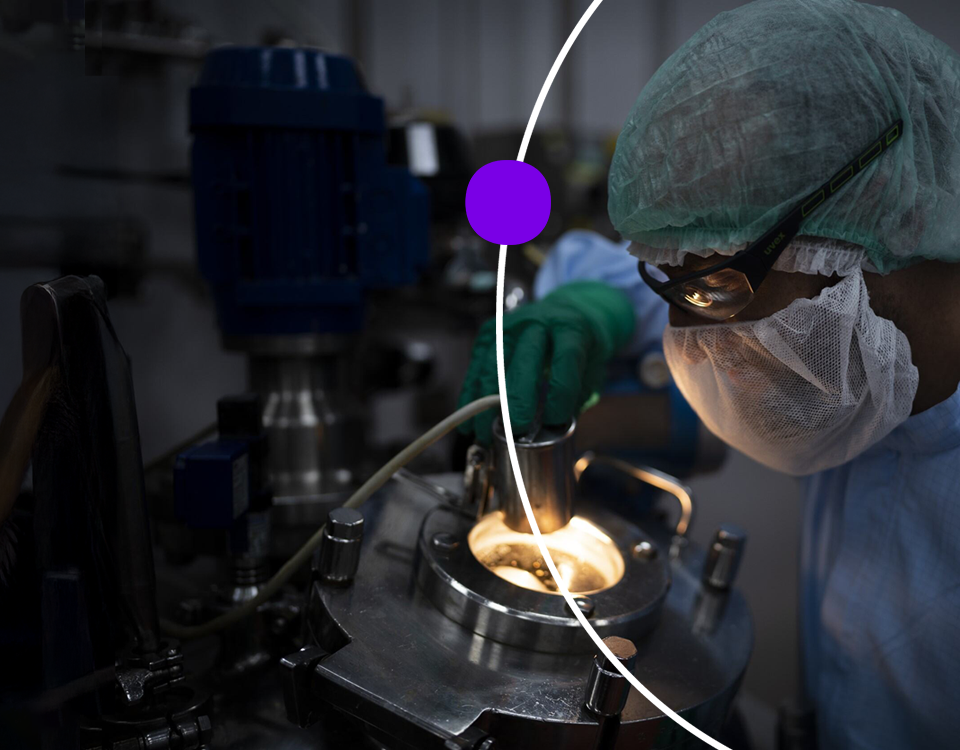

Production Technician Filling

At a glance

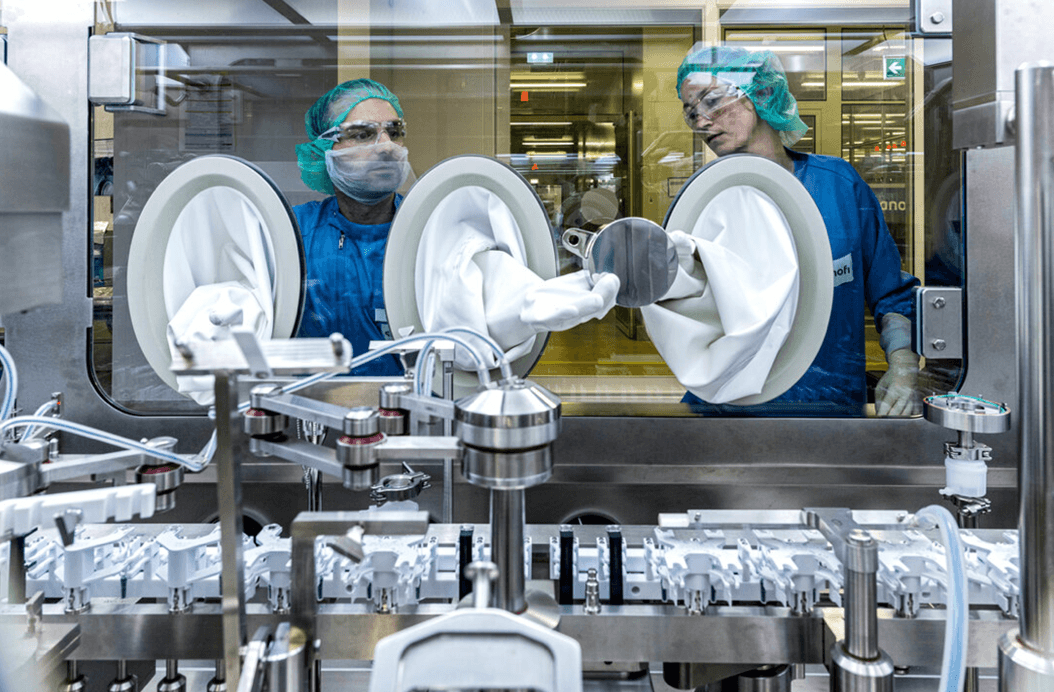

Our teams produce and deliver over 4 billion units of medicines and vaccines every year, ensuring every breakthrough gets to the people who need it most.

Our state-of-the-art facilities, AI-powered smart factories, and cutting-edge automation are redefining what’s possible: ensuring treatments reach patients faster, safer, and more sustainably than ever before. This is where your skills, ambition, and passion can shape the future of healthcare.

Job title: Production Technician Filling

Location: Swiftwater, PA

About the Job

We deliver 4.3 billion healthcare solutions to people every year, thanks to the flawless planning and meticulous eye for detail of our Manufacturing & Supply teams. With your talent and ambition, we can do even more to protect people from infectious diseases and bring hope to patients and their families.

This role is for a non-exempt employee working in the Filling Department. Their Bi-weekly pay is based on previous experience and education time.

We are an innovative global healthcare company that helps the world stay ahead of infectious diseases by delivering more than 500 million vaccine doses a year. Across different countries, our talented teams are exploring new technologies to protect people and promote healthy communities. We chase the miracles of science every single day, pursuing progress to make a real impact on millions of patients around the world.

Main Responsibilities:

Their responsibilities are, but are not limited to:

SAFETY:

Follows all procedures put into effect to ensure your safety as well as the safety of others. Participates in monthly safety meetings.

Reports all safety issues, concerns, incidents and near misses to the team leadership.

Actively participates in safety walkthroughs coordinated by the department’s safety team.

Provides input for potential safety issues as well as contributing ideas for corrective and preventative actions.

Follows effective procedures to ensure the production of a safe and efficacious product.

Utilizes +QDCI boards for Safety issues

QUALITY:

FDA audit understanding and awareness. Ensures process in areas is following proper procedures at all times

Identifies possible deviation occurrences and prevents or aids in investigations and root cause analysis.

Participate in completing at least one incident investigations, one CAPA action item, or one change control action item, along with projects.

Ensures completion and review of quality documentation (BFR’s, logbooks, etc) accurately in a timely manner for process area assigned.

Understands the function of the quality group and works with them to maintain a positive rapport.

Writes edits and reviews process documentation for completeness.

Identifies areas of deficiency and offers suggestions for improvements.

Maintains acceptable execution with no emerging negative trends in procedural deviations

DELIVERY:

Performs production in accordance with volume fluctuation, business need, and effective procedures. Must be flexible to ensure staffing for changing business volume and needs

Completes tasks and corresponding documentation as required by cGMP to ensure document completion.

Works to prepare assigned areas for the oncoming shifts to ensure continuous operation and staffing. This includes assurance of all aseptic materials.

Ensure proper septic set up and installation of aseptic fill parts and Filler set up. This is done in a Grade A environment. Must ensure maintenance of gowning and Physical dexterity to complete proper set up of machines so not to impact the safety, quality, and integrity of the product.

All other duties as assigned. Adheres to all other company time keeping and attendance policies.

Ensures all Final Container materials required for production are available prior to need. These materials must be ready for aseptic filling operations to ensure the safety, quality, purity, and integrity of the product is maintained.

Ensures the completion of Real Time SAP transactions in an accurate and timely manner to ensure accurate inventory.

COST:

Executes procedure as documented to avoid deviations.

Responsibly uses material in an efficient manner to reduce waste.

Utilized Filling Standards to capture and Record HRxHR and Change Over Activities.

Actively communicates improvement ideas, issues, concerns, etc. to team members along with providing solutions.

Works to resolve common production issues related to area of work.

INVOLVEMENT:

Works to become trained in all assigned training modules.

Trains and orients new team members (at any level) as assigned. Mentors Associate and Production techs.

Participates and leads team meetings. Understands respect, professionalism, and confidentiality.

Ensures all materials required for production are available prior to need.

Follows proper documentation as required by cGMP.

Has a thorough working knowledge of cGMP’s and works to help others understand.

Ensures all areas within the department are adequately covered at all time for current shift and upcoming shifts.

In on time and attends and participates in Shift Change.

Involved in at least one cross functional teams where necessary to complete projects in an effective and timely manner.

Training coordinator / Trainer –Train and guide Personnel in proper work procedures, use of equipment, cGMP’s, safe work techniques and SAP to assure timely signoffs and consistency in training. Maintains qualified trainer status.

All other duties as assigned.

About You

EDUCATION/EXPERIENCE:

HS diploma or equiv and 3+ years in cGMP or Pharmaceutical experience

Associates with 2 + years in cGMP or Pharmaceutical experience

Bachelors with 1 + years in cGMP or Pharmaceutical experience

Proficiency in at least but not limited to three areas of operations or product line.

Must be a qualified trainer in one or more areas. Must be proficient in at least one of the following areas: BFR review, Environmental monitoring, Utility Sampling, Documentation Coordinator, logbook review, technical writing (SWI revisions).

Must have knowledge and access to systems (SAP, Trackwise, Master, EMS, PMS, SCADA, RT Reports, Labware).

Must have knowledge and access to systems in applicable buildings and processes which have these systems (SFD, PI)

Requires good mechanical skills, computer skills and is detail oriented. Must have basic mechanical aptitude, computer skills, good comprehension skills, retention skills, troubleshooting and manual dexterity.

Prior or related cGMP or Pharmaceutical experience recommended

Why Choose Us?

Bring the miracles of science to life alongside a supportive, future-focused team.

Discover endless opportunities to grow your talent and drive your career, whether it’s through a promotion or lateral move, at home or internationally.

Enjoy a thoughtful, well-crafted rewards package that recognizes your contribution and amplifies your impact.

Take safe care of yourself and your family, with a wide range of health and wellbeing benefits including high-quality healthcare, prevention, and wellness programs and at least 14 weeks’ gender-neutral parental leave.

Sanofi Inc. and its U.S. affiliates are Equal Opportunity and Affirmative Action employers committed to a culturally diverse workforce. All qualified applicants will receive consideration for employment without regard to race; color; creed; religion; national origin; age; ancestry; nationality; marital, domestic partnership or civil union status; sex, gender, gender identity or expression; affectional or sexual orientation; disability; veteran or military status or liability for military status; domestic violence victim status; atypical cellular or blood trait; genetic information (including the refusal to submit to genetic testing) or any other characteristic protected by law.

#GD-SP

#LI-SP

#LI-Onsite

#vhd

All compensation will be determined commensurate with demonstrated experience. Employees may be eligible to participate in Company employee benefit programs, and additional benefits information can be found here.

Find out more about this location

Why work with us

- We’re problem-solvers and pioneers. United by the belief that everyone deserves a healthier future. We create best-in-class vaccines that prevent disease and protect lives.

- Innovation drives us. From AI and mRNA to next-gen science, we push the boundaries to deliver first- and best-in-class vaccines for infectious diseases worldwide.

- Growth happens here. With bold investments in R&D and world-class facilities, Sanofians across the entire vaccine lifecycle are shaping the future of global health.

- We do what’s right. Sustainability and DE&I drive our positive global impact—because the diverse communities Sanofians represent are the patients we serve.

All-in on diversity

At Sanofi, diverse perspectives fuel the best solutions for patients. Hear from Monique Vessey, our Supply Chain Transformation Leader, on how her background shapes her approach to delivering life-changing medicines.

"Manufacturing and Supply is the bridge between the science that happens in research laboratories and the people and communities we serve."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Discover more

Manufacturing & Supply Careers

Explore how Sanofi is transforming pharmaceutical manufacturing and supply chains with cutting-edge technology, digital innovation, and sustainable practices. Discover career opportunities where you can help deliver life-changing medicines efficiently and responsibly.

Accelerating Biopharma Innovation with McLaren Racing

What do Formula 1 and biopharma have in common? Speed, precision, and a drive for excellence. Discover how Sanofi is partnering with McLaren Racing to transform drug development with cutting-edge performance science.

Join our

talent community

What could we achieve together? Every Sanofian works on projects that truly make a difference to people’s lives.

Sign up today and discover our latest opportunities as soon as they’re available.