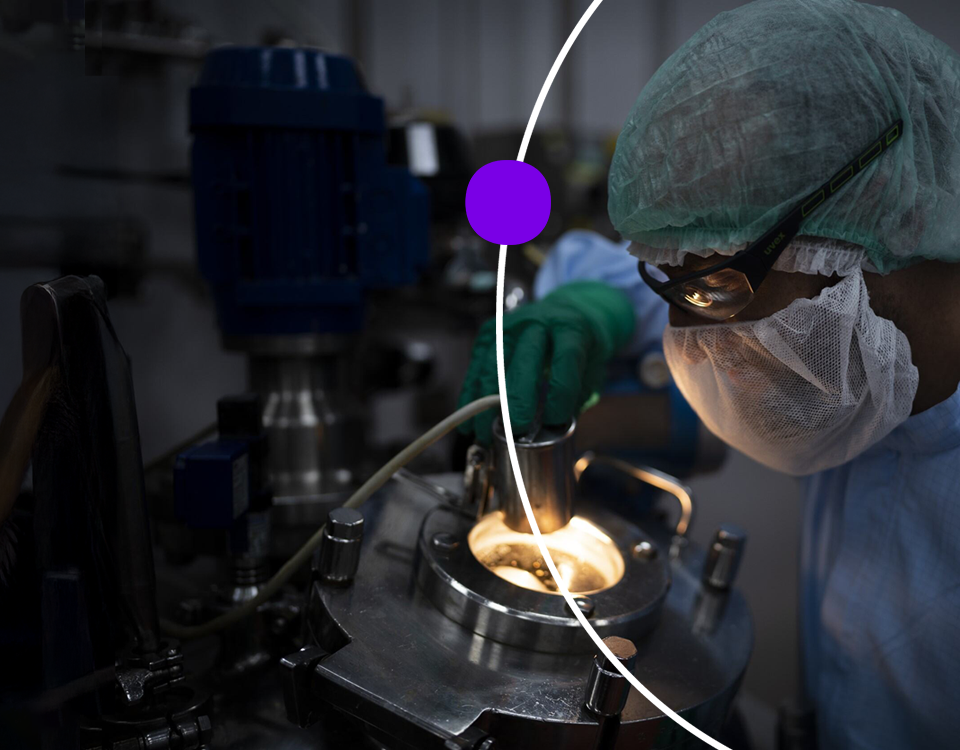

Manufacturing and Supply

Where the

miracles of

science are made

a reality for patients

Production System Engineer

At a glance

Our teams produce and deliver over 4 billion units of medicines and vaccines every year, ensuring every breakthrough gets to the people who need it most.

Our state-of-the-art facilities, AI-powered smart factories, and cutting-edge automation are redefining what’s possible: ensuring treatments reach patients faster, safer, and more sustainably than ever before. This is where your skills, ambition, and passion can shape the future of healthcare.

Reference No. R2802275

Position Title: Production System Engineer

Department: B100 - Strategy, Projects & Process

Location: Toronto, Ontario

About the Job

We deliver 4.3 billion healthcare solutions to people every year, thanks to the flawless planning and meticulous eye for detail of our Manufacturing & Supply teams. With your talent and ambition, we can do even more to protect people from infectious diseases and bring hope to patients and their families.

The production system engineer is a key role within the B100 manufacturing team. To be successful as a production system engineer, you should be an independent thinker, keen problem-solver and a team player. You should be able to diagnose technical issues, train staff, and provide effective technical recommendations. This role will work closely with multi-functional teams (Automation, Technical services, Manufacturing Technology, Quality and HSE).

The incumbent is also responsible for developing appropriate solutions to satisfy the needs of internal customers in accordance with company guidelines and procedures, and within budget and schedule commitments.

We are an innovative global healthcare company that helps the world stay ahead of infectious diseases by delivering more than 500 million vaccine doses a year. Across different countries, our talented teams are exploring new technologies to protect people and promote healthy communities. We chase the miracles of science every single day, pursuing Progress to make a real impact on millions of patients around the world.

Main Responsibilities:

Diagnose problems in the production area (Upstream, Downstream, Adsorption and MBWS) and provide technical recommendations and training to support operation to adhere to the schedule.

Develop process improvements strategies to effectively utilize equipment and materials.

Develop operational strategies to achieve production and financial objectives.

Provide engineering support for production and maintenance activities to ensure maximum production and minimum downtime.

Perform engineering analysis to reduce downtime and cost.

Evaluate and analyze current production activities and make recommendations for improvements.

Directly support operations with troubleshooting and issue resolution with respect to automation systems and equipment issue.

Manage technical projects in B100 such as replacement of equipment, building upgrades, system upgrades and assist the Engineering department.

Support new projects in B100 including mechanical completion and start-up. Participate in FAT, SAT and Critical Test plan execution.

Review the C&Q test plans and support the commissioning and qualification tasks.

Collaborate with the Maintenance & Reliability team to build and maintain a robust and up to date PM plan for B100 equipment to prevent equipment breakdowns and production delays.

Support the resolution of equipment and building issues.

Review process flow diagrams, mass balances and process descriptions including critical parameters provided by Manufacturing technology. Determine thoroughness to proceed with engineering design. Responsible to understand the process requirements and how they impact the equipment design.

Review and provide guidance on deviations prepared by technical staff.

Prepare for Regulatory inspections by drafting investigation briefing packages / hot topics as applicable.

Technical engineering support to process area. Apply lessons learned from other building/ sites to help with trouble shooting, design issues and testing specifics. Responsible to understand site specific standards and procedures.

In collaboration with platform management and other stakeholders, participate in developing appropriate technical CAPAs with a clearly defined scope to address the root cause of deviations.

Identify unsafe operations and practices and report immediately.

Supervises and monitors compliance with employment and health and safety legislation to ensure that employees work within the policies, procedures, and regulations applicable to their work.

HSE REQUIREMENT/STATEMENT

Works within the policies, procedures and regulations as required by the Company and under the Occupational Health and Safety Act.

CONTEXT OF THE JOB/MAJOR CHALLENGES

Collaborate with multi-functional teams (Automation, Technical services, Manufacturing Technology, Quality and HSE) to resolve technical issue and provide effective technical recommendations.

DIMENSIONS/SCOPE

Oversight of activities in B100 including new projects, troubleshooting, deviations and CAPAs

Financial dimensions: Impact on project delivery and cost

Human Resources dimensions: NA

Statistical dimensions: NA

Health & Safety dimensions: Oversight of safety compliance of process area.

About You

REQUIREMENTS

Ability to work in a collaborative shared space (iObeya) in a large and complex project environment where quick critical thinking and decision making is required.

Technical aptitude/understanding across a broad number of subjects including vaccine processes and equipment, HVAC systems, building and equipment maintenance.

Must understand the relationship between Good Manufacturing Practices, industry standards and their application to the manufacturing process.

Ability to effectively communicate with internal and external team members is essential.

Strong analytical skills (engineering analysis).

Familiar with computer systems validation practices.

Working knowledge of PLC’s and automation in DCS platform.

Experience authoring and reviewing standard operating procedures, on-the-job-trainings, and other controlled documents.

Working knowledge of unit operations typically used in biotech and vaccine manufacturing such as Upstream, Downstream, Adsorption , MBWS, Formulation, sterilization in place (SIP) and cleaning in place (CIP).

Knowledge of clean utility design such as WFI, clean steam and clean air systems is desirable.

Must understand the relationship between Good Manufacturing Practices, industry standards and their application to the manufacturing process.

Management skills to ensure project meets budget/timeline.

Act for Change, Cooperate Transversally, Commit to Customers, Strive for Results, Think Strategically, Develop People, Make Decisions and Lead Teams.

Technical aptitude/understanding of digital system.

Education/Certifications

Minimum bachelor’s in Engineering, Microbiology, Biochemistry, Biotechnology or Related Science or higher-Level Education.

Experience

3 + years of experience in vaccine manufacturing / large project experience are required.

Competencies

Strive for results

Cooperate transversally

Act for change

Commit to customers

Why Choose Us?

Bring the miracles of science to life alongside a supportive, future-focused team.

Discover endless opportunities to grow your talent and drive your career, whether it’s through a promotion or lateral move, at home or internationally.

Enjoy a thoughtful, well-crafted rewards package that recognizes your contribution and amplifies your impact.

Take good care of yourself and your family, with a wide range of health and wellbeing benefits including high-quality healthcare, prevention and wellness programs

This position is for a new vacant role that we are actively hiring for.

Sanofi is an equal opportunity employer committed to diversity and inclusion. Our goal is to attract, develop and retain highly talented employees from diverse backgrounds, allowing us to benefit from a wide variety of experiences and perspectives. We welcome and encourage applications from all qualified applicants. Accommodations for persons with disabilities required during the recruitment process are available upon request.

#GD-SP

#LI-SP

#LI-Onsite

All compensation will be determined commensurate with demonstrated experience. Employees may be eligible to participate in Company employee benefit programs, and additional benefits information can be found here.

Les employés peuvent être admissibles à participer aux programmes d'avantages sociaux de l'entreprise. Des informations supplémentaires sur les avantages sociaux peuvent être trouvées ici.

Find out more about this location

Why work with us

- We’re problem-solvers and pioneers. United by the belief that everyone deserves a healthier future. We create best-in-class vaccines that prevent disease and protect lives.

- Innovation drives us. From AI and mRNA to next-gen science, we push the boundaries to deliver first- and best-in-class vaccines for infectious diseases worldwide.

- Growth happens here. With bold investments in R&D and world-class facilities, Sanofians across the entire vaccine lifecycle are shaping the future of global health.

- We do what’s right. Sustainability and DE&I drive our positive global impact—because the diverse communities Sanofians represent are the patients we serve.

All-in on diversity

At Sanofi, diverse perspectives fuel the best solutions for patients. Hear from Monique Vessey, our Supply Chain Transformation Leader, on how her background shapes her approach to delivering life-changing medicines.

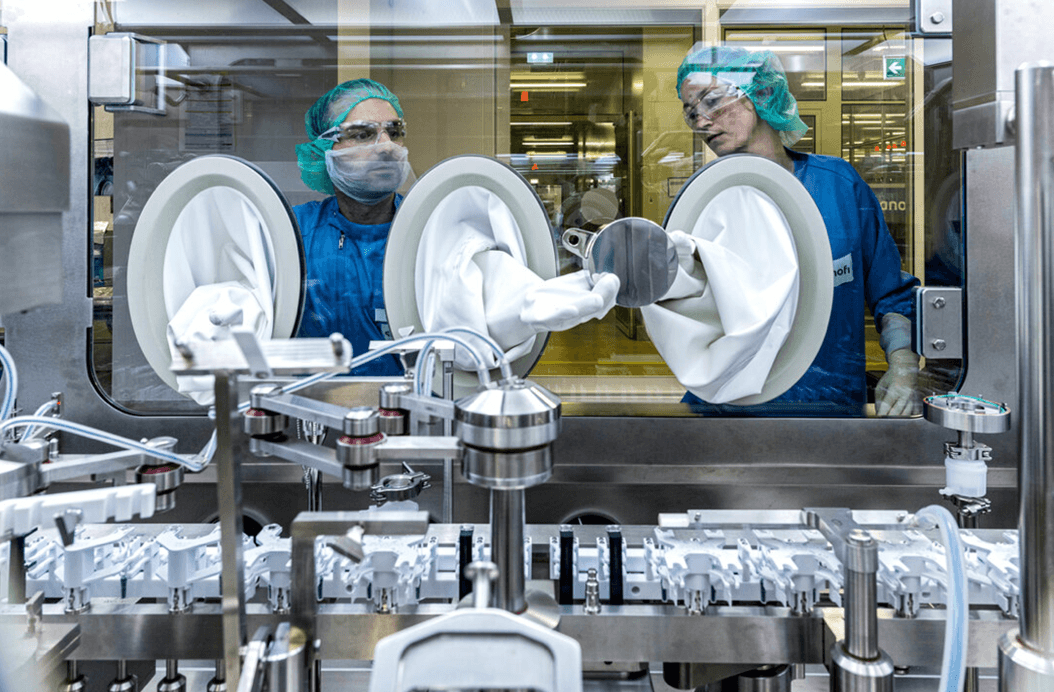

"Manufacturing and Supply is the bridge between the science that happens in research laboratories and the people and communities we serve."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Discover more

Manufacturing & Supply Careers

Explore how Sanofi is transforming pharmaceutical manufacturing and supply chains with cutting-edge technology, digital innovation, and sustainable practices. Discover career opportunities where you can help deliver life-changing medicines efficiently and responsibly.

Accelerating Biopharma Innovation with McLaren Racing

What do Formula 1 and biopharma have in common? Speed, precision, and a drive for excellence. Discover how Sanofi is partnering with McLaren Racing to transform drug development with cutting-edge performance science.

Join our

talent community

What could we achieve together? Every Sanofian works on projects that truly make a difference to people’s lives.

Sign up today and discover our latest opportunities as soon as they’re available.