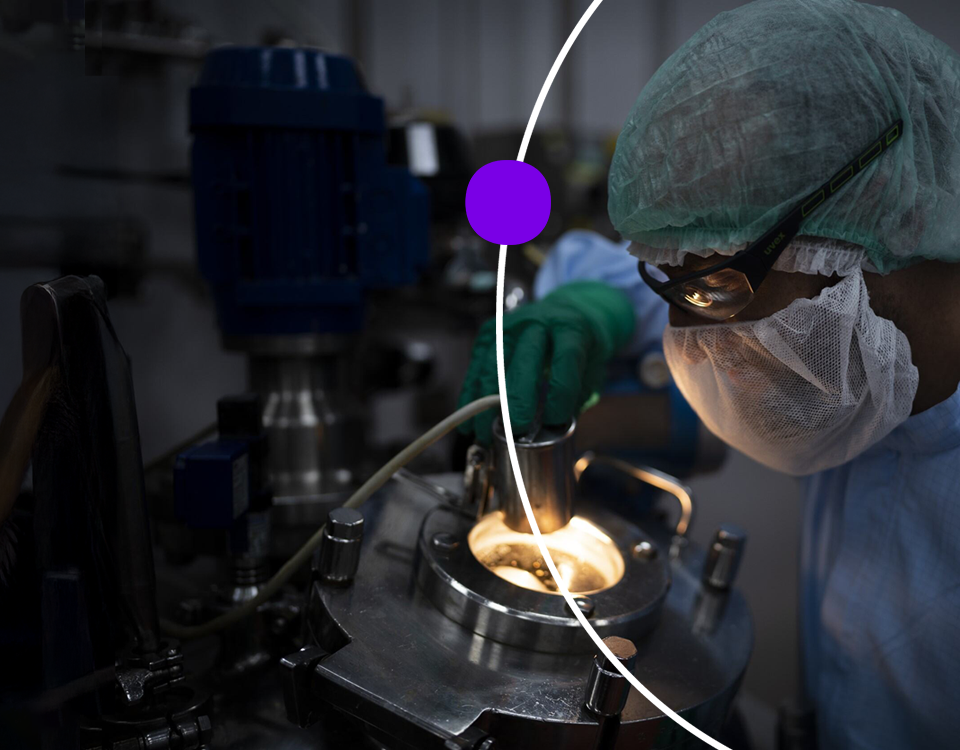

Activités Industrielles

Là où les miracles

de la science

deviennent une réalité pour les patients

Technologist- Vaccines

En bref

Nos équipes produisent et livrent chaque année plus de 4 milliards de médicaments et de vaccins, veillant à ce que chaque avancée soit accessible à ceux qui en ont le plus besoin. Grâce à des infrastructures ultra-modernes, des usines intelligentes pilotées par l’IA et une automatisation de pointe, nous repoussons les limites pour garantir que nos traitements parviennent aux patients plus rapidement, en toute sécurité et de manière plus durable que jamais. C’est ici que votre expertise, votre ambition et votre passion peuvent façonner l’avenir de la santé.

R2796209 Technologist- Vaccines

Duration: Fixed Term Contract End Date: April 30, 2026

Location: Toronto, Ontario

About the Job

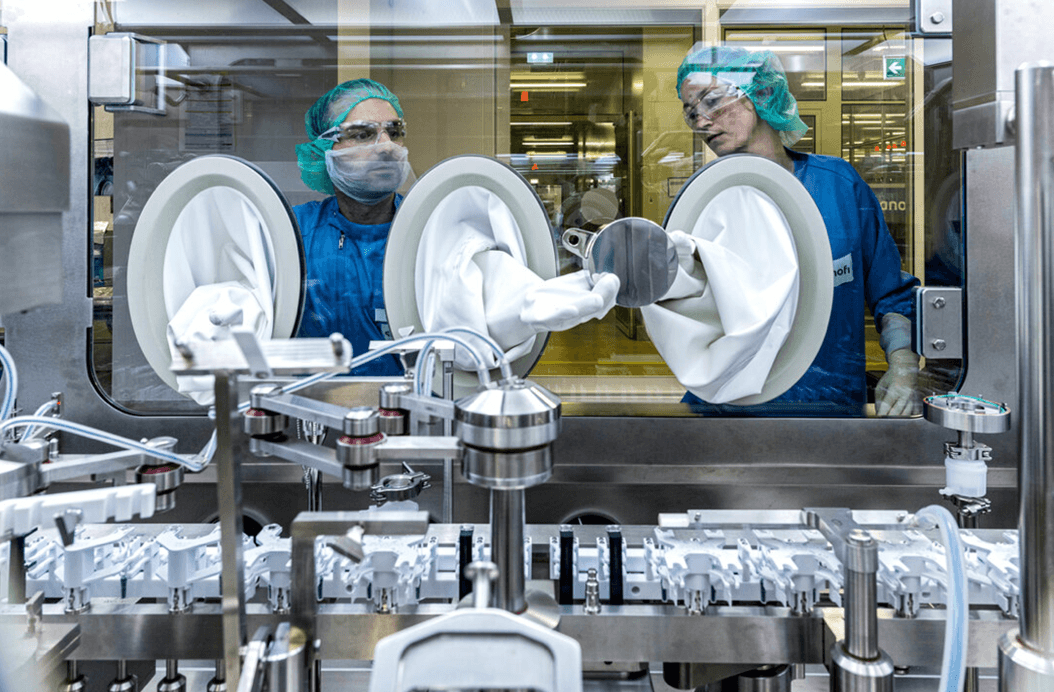

Sanofi's global vaccines business unit partners with the public health, medical and scientific communities to improve access to life-protecting vaccines and increase vaccination coverage, while striving to develop new and improved vaccines to enhance health and well-being.

At Sanofi, we chase the miracles of science to improve people’s lives. We believe our cutting-edge science and manufacturing, fueled by data and digital technologies, have the potential to transform the practice of medicine, turning the impossible into possible for millions of people.

Major Responsibilities:

Efficiently, Operate and Complete Daily Tasks within the B90 Media Chemical. Raw Material Dispensing and Media Formulation Laboratory:

Follow strict adherence to specific SOP's, cGMP's and specified process validation protocols.

Work with minimal supervision to maintain precise inventory of approximately 300 chemicals used in the preparation of over 250 buffers, acids, bases, agarsand tissue growth culture medium.

Manufacture large volumes in high demand to customers in Component. Pertussis (CP89 and CP90), PPD, Diphtheria, Tetanus, Final Product (Building90, 92), Adsorption Formulation (Building 90, 92), QC Bacteriology, M-Tech, Validation and Research and Development Departments.

Responsible for receiving chemical raw materials, scanning into SAP, labeling, thoroughly cleaning and wrapping with plastic to minimize dust and particulates, before placed in storage.

In the Media laboratory all duties performed are entered concurrently into Batch Production Records; each chemical is accurately selected, correctly labeled (using SAP system), weighed out in appropriate vessels and stored at the required conditions for the particular media being formulated.

Formulation of Media and Diluents as per SOP's and cGMP:

Accurately formulate media:

Complex Components Pertussis media for seed propagation, intermediate and production scale fermentation, critical buffers and dilution materials

Tetanus, Diphtheria, complex multi-stage media, removal of toxin inhibiting materials, filtration of media and preparation of diluents and intermediate buffers.

PPD, Final Formulation, Adsorption, for final dilution buffers, supply of adjuvant and support intermediate solutions.

M-Tech, QC Bacteriology, Validation, R&D in accordance with SOP's and cGMP's, under a highly controlled environment for testing solutions and final release test media

Formulation of licensed materials is done independently, which includes the precise weighing of chemical components, thorough mixing with WFI, sterile filtration, the distribution to bulk containers and send samples to QC for testing.

Adjustment of pH by the addition of base or acid, dilution, conductivity reading, osmolality reading and filter integrity testing.

Requires extensive and detailed calculations and concurrent documentations as the job is being performed.

Verifier for co-worker when tasks are performed, materials are added, or in-process tests for pH, conductivity and osmolality are performed.

Sterile Filtration of Final Product in Grade A/B Areas:

Works independently within the clean room area executing the critical work via aseptic processes.

Thorough inspection of all equipment used within the clean room area and process related equipment.

Aseptic process to avoid contamination of materials or products, primarily responsible for the manufacturing of adjuvant used in the purified antigen process and in the final formulation process.

Preparation of clean room hoods and equipment set-up for the preparation of testing materials, dispensing of critical release-testing media plates, production related agar plates.

Performs final sterile filtration, dispensing and sampling of Aluminum., Phosphate, I 0% Triton, 5 % Tween 80 and other types of media.

Aseptically adjust pH by adding the base into the solution with precision and accuracy.

Extract QC samples from final bulk container for sterility and aluminum content.

During filtration, dispensing and sampling, extensive environmental monitoring must be performed including personal touch plates, settle plates, equipment touch plates, facility touch plates, air-borne particle counting, etc.

Perform semi-annual Aseptic Process Simulation Study for protocol review and creation of process orders for QO Sterility Testing via SAP.

Calibration and Monitoring of Scientific Equipment and Systems:

Performs daily or routine (as per schedule) calibration of pH meters, osmometers, weigh scales and balances; performs monitoring of magnehelic gauges, FMS (Facility Monitoring System) temperature and relative humidity and completion of other prescribed log books entries.

Maintenance of WFI system, sterile collection of WFI samples to be delivered for QC testing.

Performs appropriate environmental and personal monitoring according to strict schedules detailed in area SOP's and corporate policies.

Provide relevant information to Quality Operation Contamination Control in any investigation with regards to Environmental Incident Reports that occur in

Bacterial Media Production Area by providing all the requested data and documents to solve the issue.

Daily maintain all lab equipment to ensure proper function, certification and up to date.

Accurate Record Keeping and Inventory Monitoring:

Accurately and concurrently completes: batch production records, sample labels, and test requisitions, environmental monitoring data sheets.

Responsible for checking release and date status of all raw materials in SAP prior to use; makes all relevant SAP data entries and transactions related to inventory consumption and product formulation.

Order material via SAP and NEXT.

Develops and Revises SOP's, BPR's Process Improvements/Efficiencies:

Suggest changes to SOP's and BPR's intended to streamline production methods.

Improve efficiencies, improve adherence to cGMPs or to assure better quality material.

Create new SOP's or BPR's when our customers require new media formulations.

Sterile Filtration and Dispensing of Various Media Products in Class "C-Cl" Laboratories.

Performs final sterile filtration dispensing of any media type made in class C-CI laboratories. The work must be performed aseptically. During dispensing and sampling, extensive environmental monitoring must be performed including personal touch plate, settle plates, equipment touch plates, facility touch plate, air borne particle counting, etc. Integrity test of each liquid filter must be done pre-and post-use. Dispensing of agar plates, Roux bottles is also done in this area.

About You

Minimum three (3) years Diploma (Microbiology, Chemistry and Laboratory related courses), plus a minimum of three (3) year of previous relevant work experience.

Preferred three (3) years B.Sc (Microbiology, Chemistry, Biochemis), plus a minimum of one (1) year of previous relevant work experience.

Strong knowledge of Decision Making.

Hours Of Work:

Inclusive from Monday to Friday: 10:00 AM to 06:00 PM.

This is subject to change at any time, and it should not be construed as limiting the right of the company to make such change to meet the requirements of the operation

Why Choose Us?

Bring the miracles of science to life alongside a supportive, future-focused team.

Mandatory Application Requirement: Your Workday application form must be complete, and a copy of your resume MUST be attached in the Workday application form, at the time you submit your Workday application, otherwise your application will not be considered for this position

This position is for a current vacant role that we are actively hiring for.

Sanofi is an equal opportunity employer committed to diversity and inclusion. Our goal is to attract, develop and retain highly talented employees from diverse backgrounds, allowing us to benefit from a wide variety of experiences and perspectives. We welcome and encourage applications from all qualified applicants. Accommodations for persons with disabilities required during the recruitment process are available upon request.

#GD-SP

#LI-SP

#LI-Onsite

All compensation will be determined commensurate with demonstrated experience. Employees may be eligible to participate in Company employee benefit programs, and additional benefits information can be found here.

Les employés peuvent être admissibles à participer aux programmes d'avantages sociaux de l'entreprise. Des informations supplémentaires sur les avantages sociaux peuvent être trouvées ici.

Toujours Progresser. Découvrir l’Extraordinaire..

Le progrès ne se fait pas tout seul, ce sont les gens qui le construisent : des gens d'horizons différents, dans des lieux différents, dans des rôles différents, mais tous réunis par une même motivation : la volonté de rendre l’impossible possible. Et si vous rejoigniez cet élan ? Afin de poursuivre le changement, adopter de nouvelles idées et explorer toutes les opportunités que nous avons à offrir. Ensemble, continuons de progresser. Et partons à la découverte de l'extraordinaire.

Chez Sanofi, nous croyons en l’égalité des chances pour tout le monde, indépendamment de l’origine, de la couleur de peau, des croyances, du genre, de l'orientation sexuelle, de l'âge, de la citoyenneté, de l'état civil, du handicap ou de l’identité de genre.

Cette offre d’emploi est ouverte à toutes et tous, quel que soit le genre auquel s’identifie le candidat ou la candidate.

Regardez notre vidéo ALL IN et consultez nos actions en faveur de la diversité, de l'équité et de l'inclusion sur sanofi.com !

En savoir plus

sur ce site

Pourquoi nous rejoindre ?

- Nous ne faisons pas que fabriquer des médicaments—nous créons un impact. Grâce à notre réseau international d’installations de pointe, nous veillons à ce que les patients reçoivent les traitements dont ils ont besoin, au moment où ils en ont besoin.

- L’innovation est notre moteur. De la fabrication pilotée par l’IA aux méthodes de production inédites, nous repoussons les limites de l’efficacité et de la performance.

- Ici, vous évoluez. Que ce soit en production, en qualité, en ingénierie ou en supply chain, vous collaborerez avec des experts de renom, développerez vos compétences et contribuerez à façonner l’avenir de l’industrie pharmaceutique.

- Nous faisons ce qui est juste. Sécurité, durabilité, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir.

Tous engagés pour la diversité

Chez Sanofi, la diversité des perspectives est une source d’innovation au service des patients. Découvrez Hamza Laajaj, Chef de projet déploiement applicatif à Neuville-sur-Saône, et son engagement pour un environnement inclusif où chaque voix compte. Pour lui, c’est en embrassant la diversité que nous libérons l’innovation et repoussons les limites de la santé.

"Nous faisons ce qui est juste. Sécurité, développement durable, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

En savoir plus

Carrières dans les Activités Industrielles

Découvrez comment Sanofi révolutionne la production pharmaceutique et les chaînes d’approvisionnement grâce aux technologies de pointe, à l’innovation digitale et à des pratiques durables. Rejoignez-nous pour contribuer à la distribution efficace et responsable de médicaments essentiels.

Accélérer l’innovation biopharma avec McLaren Racing

Qu’ont en commun la Formule 1 et la biopharma ? La vitesse, la précision et l’excellence. Découvrez comment Sanofi et McLaren Racing repoussent les limites du développement de médicaments grâce aux sciences de la performance de pointe.

Rejoignez notre communauté

de talents

Que pourrions-nous accomplir ensemble ? Chaque Sanofien travaille sur des projets qui ont un véritable impact sur la vie des gens.

Inscrivez-vous dès aujourd'hui et découvrez nos dernières opportunités dès qu'elles seront disponibles.