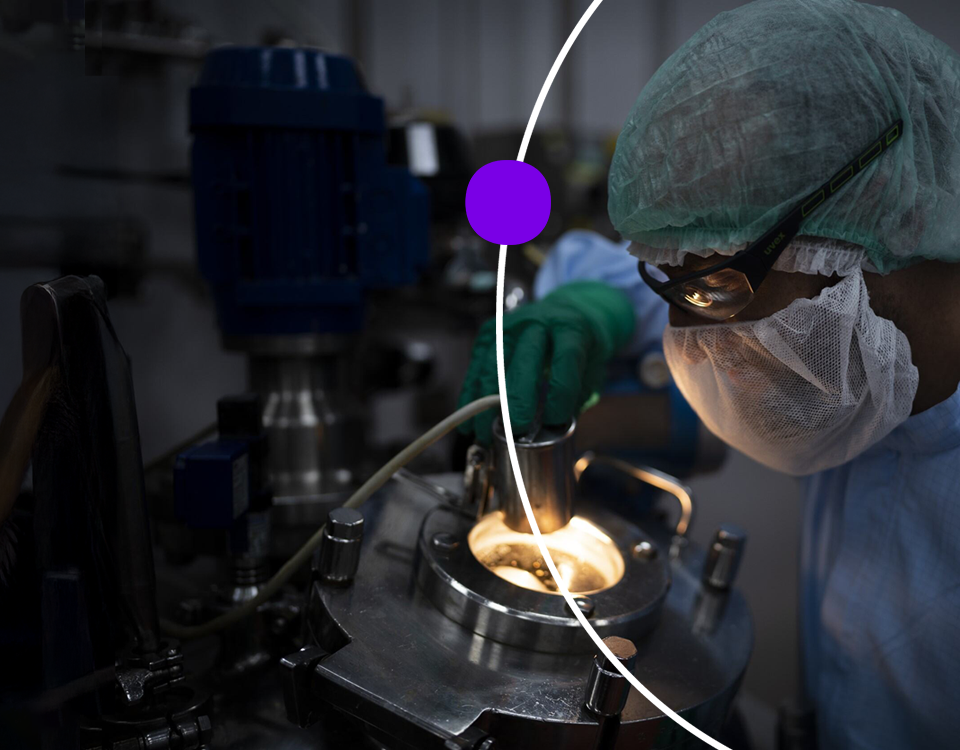

Activités Industrielles

Là où les miracles

de la science

deviennent une réalité pour les patients

Executive Production

En bref

Nos équipes produisent et livrent chaque année plus de 4 milliards de médicaments et de vaccins, veillant à ce que chaque avancée soit accessible à ceux qui en ont le plus besoin. Grâce à des infrastructures ultra-modernes, des usines intelligentes pilotées par l’IA et une automatisation de pointe, nous repoussons les limites pour garantir que nos traitements parviennent aux patients plus rapidement, en toute sécurité et de manière plus durable que jamais. C’est ici que votre expertise, votre ambition et votre passion peuvent façonner l’avenir de la santé.

Job title: Assistant Manager Production

Grade: L1-2

Hiring Manager: Mr. Manas Brahma

Location : Goa Site, Verna Industrial Estate, Salcete, Goa, India.

% Remote working and % of travel expected: 100% at Site

Job type: Permanent Full time

About the job

Our Team:

We are the team (Production) of about 150 permanent employees and having state-of-the-art manufacturing facility for tablet manufacturing. Our Purpose is to provide the medicine to patient with outmost quality and on time but with safety. We are highly motivated and safety driven team with a good bonding.

Main responsibilities:

Resource and Time Management

Allocation of scheduled activity to Operators in the shift as per Production Plan.

Allocation of Manpower to associated activity in the shift wherever needed.

Allocation of necessary accessories to the operator/manpower as and when needed for completion of the activity.

Maintaining discipline amongst the manpower resources at all times and be a role model by strictly abiding the rules and regulation mentioned in certified standing orders.

Ensure to complete the scheduled activity (output) within standard time.

Prioritize activity in order to provide supply as per market demand.

Shift handover and Vital Communication sharing

To communicate effectively with shift supervisors and sub-ordinates of the completed activity in the shift.

Share Vital Information regarding product critical to manufacturing during shift handovers through Status Board and Direct Communication.

Line Compliance and Adherence to Quality standards

Ensure that the activity executed by the Operator/Manpower is adhering to the effective SOP’s and is within the specified parameters/standard in BMR.

Identify, troubleshoot, report the Quality defects online if noticed and adhere to stringent AQL checks as specified in Batch Manufacturing Record.

Ensure to compile, check and submit the completed batch manufacturing records to Quality assurance.

Ensure that the products are manufactured and stored as per the requirements, ensure implementation of the quality system, Good documentation practice for BR, logbooks and Log cards, ensure that data integrity attributes are followed.

Production planning and scheduling

Receive production plan from Manager-Production, plan, execute, interact with cross functional departments for communicating requirement for completion of plan.

Monitor daily activity, Ensure that Posting of the completed batches in SAP is carried d out, Plan changeovers in order to maximise activity in scheduled time for Dispensing, Granulation, Mixing and compression/coating.

Maintain adequate WIP levels and document for all products manufactured at Goa to achieve scheduled production with optimum resources.

Implement Process Excellence and Projects

Improve processes, cycle time, yields, optimum utilization of capacity in order to improve cost of goods manufactured.

Devise Action plan in co-ordination with other team members to improve the process, quality and productivity.

Update OEE and other equipment details in designated records from time to time and assist the Lean Management in gathering of required accurate data for process excellence.

Training and Development

Confirm that you are trained on relevant SOP’s before proceeding for execution of the activity.

Train and help subordinate to implement GMP/HSE systems and development of people.

Ensure all the new joiners are trained on the job before assigning them the job.

Train and help direct reports/sub-ordinates to implement GMP/HSE systems and development of people. Also training & guidance to subordinates for new product transfer strategy & documentation process (Validation protocol, BPR etc.).

Adherence to Site HSE Systems

Ensure that the implementation of HSE systems, safe working conditions and maintain a culture of continuous improvement.

Initiate the departmental safety committee meeting.

Take suggestion from associates to improve the work conditions with great safety and zero risk.

Periodic review of the implemented procedures and evaluation of the same.

Train people on safety and their job to ensure zero LTI and IWLT at workplace.

Adherence to all health safety & environmental aspects as required by company policies and procedures.

Ensure that the implementation of HSE systems, safe working conditions and maintain a culture of continuous improvement.

Conducting daily training in the +QDCI meeting address any unsafe condition.

Take suggestion from direct reports/sub ordinates to improve the work conditions with great safety and zero risk.

Periodic review of the implemented procedures and evaluation of the same.

Train people on safety and their job to ensure zero LTI and IWLT at workplace.

Introduction of New Products/Transferred products at Site (Validation)

Co-ordinate in new product introduction/transfer (Validation), make schedule batches, make protocol and reports, validate manufacturing activity, and ensure release as per plan to successfully implement products to the Goa site.

To Prepare Validation protocol for pilot scale batches, engineering batches and commercial scale batches.

Execution and implementation of validation activity as per protocol.

Preparation and approval of validation reports. Revision of MFR and BMR for inclusion of Post validation changes.

Quality Compliance activities

Ensure completion and implementation of compliance activities in manufacturing i.e., deviation investigation, OOS and OOT investigation, CAPA implementation. Regulatory audit handling and CAPA implementation of the same.

SOP revision for routine revision and Inclusion of corrective actions and preventive actions.

Change Control management: Logging of change control and ensure to close the same after completion of activity in defined time.

Revision of MFR, BMR: Revision for Inclusion/exclusion of material codes, Inclusion of Corrective actions/Preventive actions or any other changes required.

Ensure to coordinate with Quality Assurance for implementation of Corrective actions and preventive actions for Quality events.

Effectiveness review for shopfloor CAPA’s.

Ensure Audit readiness for the Site at all times by following the procedures laid in effective SOP’s.

Qualification & Change Control

Assist in Qualification of any new Equipment/Modification: make URS, PQ protocol and reports.

Ensure equipment qualification is as per GMP standards and User requirements along with supporting department.

About you

Experience: Preferably2-4 Years

Soft skills: MS Word, Excel, SAP, Power point

Technical skills: Experience in tablet manufacturing.

Education: B.Pharm / M.Pharm

Languages: Must know English and able to write and communicate in english

Beware of Job Scams: Sanofi Fraud Notice:

As you conduct your job search, please beware of the possibility that scammers may post fraudulent job openings or send fraudulent communications (email, SMS, WhatsApp or Messenger messages pretending to be from Sanofi) regarding potential job postings or offers in an attempt to encourage the job seeker to disclose financial or personal information. We do not make any payments to or ask candidates for any fees as part of the application process. In most cases you can expect to hear directly from a member of our recruiting team with a legitimate @sanofi.com email address, but you may receive communications from one of our recruiting partners as well. Consequently, you should always conduct research to ensure a posting and/or offer is legitimate and you should never provide personal or financial information unless you are certain that the request is legitimate. If you are concerned that an offer of employment with Sanofi might be a scam, please verify by searching for the posting on the Careers webpage

null

En savoir plus

sur ce site

Pourquoi nous rejoindre ?

- Nous ne faisons pas que fabriquer des médicaments—nous créons un impact. Grâce à notre réseau international d’installations de pointe, nous veillons à ce que les patients reçoivent les traitements dont ils ont besoin, au moment où ils en ont besoin.

- L’innovation est notre moteur. De la fabrication pilotée par l’IA aux méthodes de production inédites, nous repoussons les limites de l’efficacité et de la performance.

- Ici, vous évoluez. Que ce soit en production, en qualité, en ingénierie ou en supply chain, vous collaborerez avec des experts de renom, développerez vos compétences et contribuerez à façonner l’avenir de l’industrie pharmaceutique.

- Nous faisons ce qui est juste. Sécurité, durabilité, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir.

Tous engagés pour la diversité

Chez Sanofi, la diversité des perspectives est une source d’innovation au service des patients. Découvrez Hamza Laajaj, Chef de projet déploiement applicatif à Neuville-sur-Saône, et son engagement pour un environnement inclusif où chaque voix compte. Pour lui, c’est en embrassant la diversité que nous libérons l’innovation et repoussons les limites de la santé.

"Nous faisons ce qui est juste. Sécurité, développement durable, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

En savoir plus

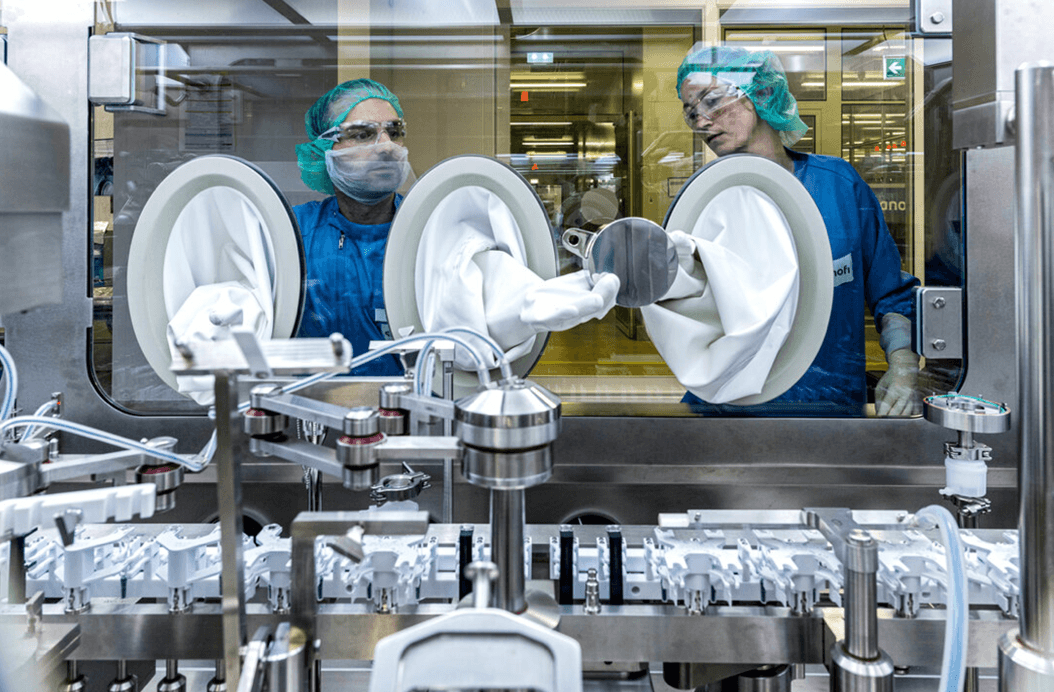

Carrières dans les Activités Industrielles

Découvrez comment Sanofi révolutionne la production pharmaceutique et les chaînes d’approvisionnement grâce aux technologies de pointe, à l’innovation digitale et à des pratiques durables. Rejoignez-nous pour contribuer à la distribution efficace et responsable de médicaments essentiels.

Accélérer l’innovation biopharma avec McLaren Racing

Qu’ont en commun la Formule 1 et la biopharma ? La vitesse, la précision et l’excellence. Découvrez comment Sanofi et McLaren Racing repoussent les limites du développement de médicaments grâce aux sciences de la performance de pointe.

Rejoignez notre communauté

de talents

Que pourrions-nous accomplir ensemble ? Chaque Sanofien travaille sur des projets qui ont un véritable impact sur la vie des gens.

Inscrivez-vous dès aujourd'hui et découvrez nos dernières opportunités dès qu'elles seront disponibles.